Combination Weighers Improve Efficiency And Quality For Food Production

- Applications of Combination Weighers in Food Production

- 1. Large Snack Manufacturers

- 2. Staple Food Processing Companies

- 3. Frozen Food Companies

- 4. Fresh Food Processing Companies

- 5. Bakery Companies

- 6. Health Food and Nutritional Supplement Companies

- Guangdong Kenwei Intellectualized Machinery Co., Ltd.

Combination weighers, also known as multihead weighers, are transforming food production with unmatched accuracy and efficiency. From snacks and staples to frozen, fresh, bakery, and health foods, they ensure consistent weight, reduce waste, and boost productivity. Trusted by global brands, Guangdong Kenwei delivers reliable weighing solutions for every industry.

A combination weigher, also known as a multihead weigher, is a high-precision automatic weighing device powered by advanced technology and intelligent algorithms. It is widely used in industries with strict accuracy requirements, including food production, pharmaceuticals, and daily chemicals.

In the food industry, combination weighers improve efficiency and quality by delivering precise measurements, automated processes, and intelligent management. They help companies reduce labor costs, minimize errors, and achieve consistent product standards.

Applications of Combination Weighers in Food Production

1. Large Snack Manufacturers

Snack producers such as Lay’s (potato chips) and Qiaqia (nuts and seeds) face high production volumes and diverse packaging needs. Combination weighers enable fast, accurate weighing of products like chips, nuts, and candies. For example, Lay’s uses multihead weighers to ensure each bag of chips meets exact weight requirements, supporting multiple packaging formats from single-serve to family packs.

2. Staple Food Processing Companies

Producers of rice, flour, and noodles—such as Golden Dragon Fish (rice and flour) and Chen Keming (noodles)—use combination weighers to guarantee accurate bag weights (e.g., 500g, 1kg, 5kg). In noodle production, these machines handle different product shapes (dried or rolled noodles) and packaging types, including retail bags and gift boxes.

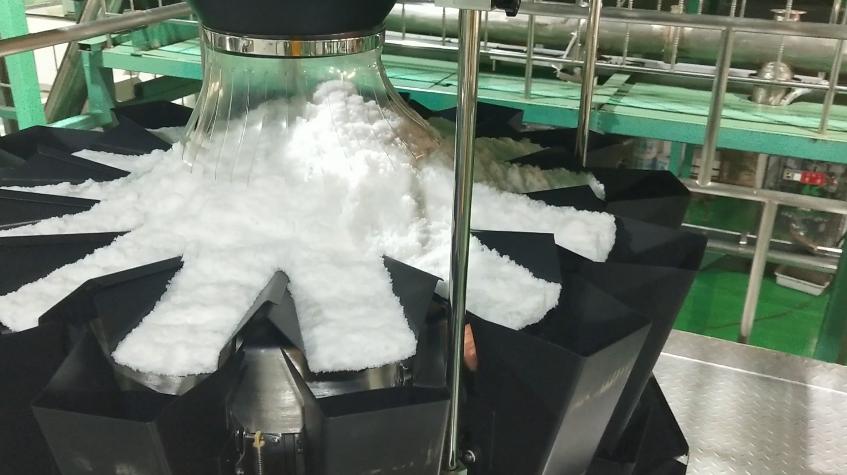

3. Frozen Food Companies

Brands like Sanquan and Sinian (dumplings, glutinous rice balls) and Guolian Aquatic Products (frozen seafood) rely on combination weighers for frozen production lines. These machines perform stably in low-temperature environments, weighing dumplings or rice balls by piece count, while ensuring seafood and meat packaging meets strict weight standards.

4. Fresh Food Processing Companies

Producers such as Shuanghui (meat) and Zhangzidao (seafood) benefit from accurate weighing of fresh meat, seafood, vegetables, and fruits. Combination weighers integrate with automated packaging systems to reduce manual handling and maintain quality. For fruits and vegetables, they can adapt to varied shapes, sizes, and densities—even weighing wet or irregular produce with precision.

5. Bakery Companies

Bakeries including Oreo (biscuits) and Taoli (bread) use combination weighers to ensure consistent product weights. In biscuit production, weighers handle multiple shapes and flavors, while in bread production they manage both single and multi-pack formats, boosting packaging efficiency and product consistency.

6. Health Food and Nutritional Supplement Companies

Producers of protein powders, nut powders, and traditional supplements such as donkey-hide gelatin cakes require extremely precise weighing. Combination weighers ensure consistent fills in containers or pouches, helping health food companies maintain quality standards and build consumer trust.

Guangdong Kenwei Intellectualized Machinery Co., Ltd.

Guangdong Kenwei has specialized in intelligent weighing equipment for 19 years and is a leading combination weigher manufacturer in China. Its product range covers 1 to 32 heads, serving applications from confectionery and snacks to fresh foods and powdered products.

Key strengths include:

-

Stable quality (two-year failure rate <2%)

-

High accuracy (±0.1g)

-

Strong global reputation with 1,500+ strategic partners worldwide

With its advanced technology and trusted performance, Guangdong Kenwei is a reliable partner for food manufacturers and automatic packaging equipment providers.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

The Standard Multihead Weigher features a high-speed, spring-free hopper with a new aluminum shell design, ensuring stable and fast weighing performance. The integrative welding of the mouthpiece case and middle seat enhances the overall machine strength. Ideal for weighing granular products like melon seeds, peanuts, nuts, almonds, raisins, candies, and pistachios, this 14-head multihead weigher offers hopper options of 1.6L and 2L. With a maximum weighing speed of 120 packs per minute, it delivers rapid and accurate results for high-volume operations.

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei