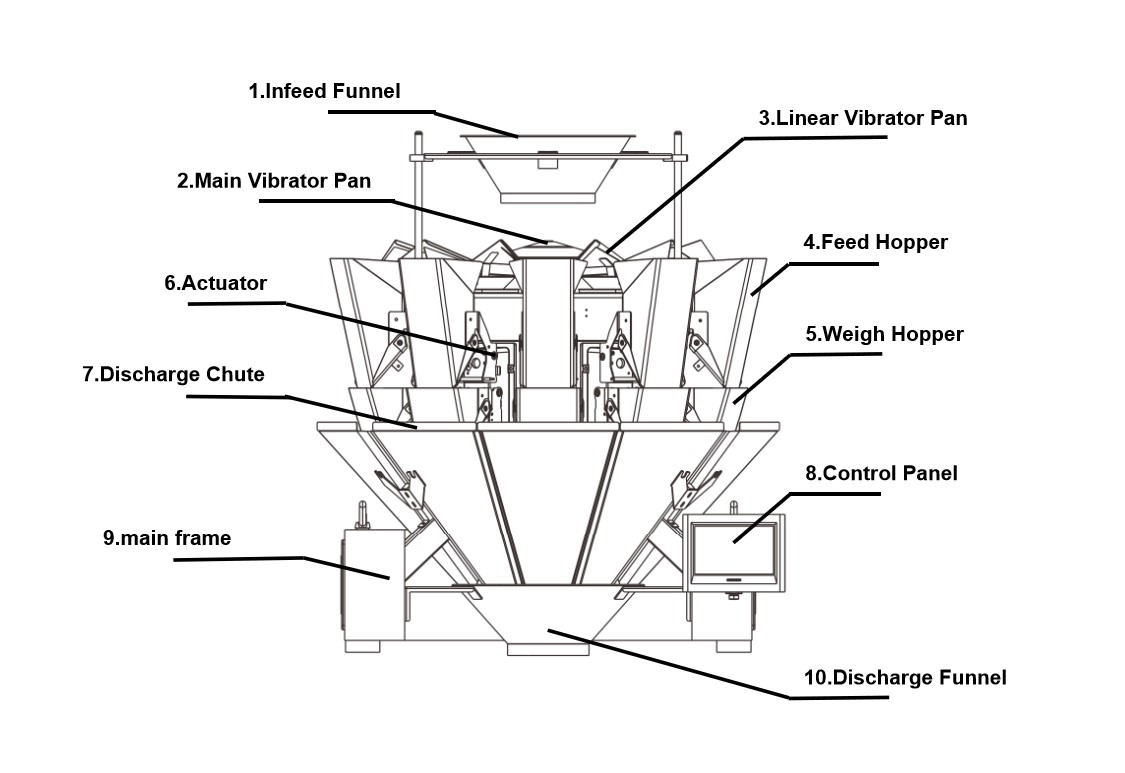

Combination Weigher Weighing Principle and Workflow

Discover how a combination weigher, also known as a multihead weigher, boosts efficiency and accuracy in food and packaging industries. With advanced weighing principles and smart workflow, Kenwei delivers reliable, high-speed solutions that cut costs, ensure quality, and maximize production.

A combination weigher, also known as a multihead weigher, is a high-precision automatic weighing device that applies advanced technology and intelligent algorithms. It is widely used in industries with strict measurement requirements, including food, pharmaceuticals, and daily chemicals.

By ensuring accurate measurement, automation, and intelligent management, combination weighers enhance production efficiency and product quality. They can automate the entire packaging process—from feeding, metering, and filling to date printing—greatly reducing manual labor and operational costs.

What Is the Weighing Principle of a Combination Weigher?

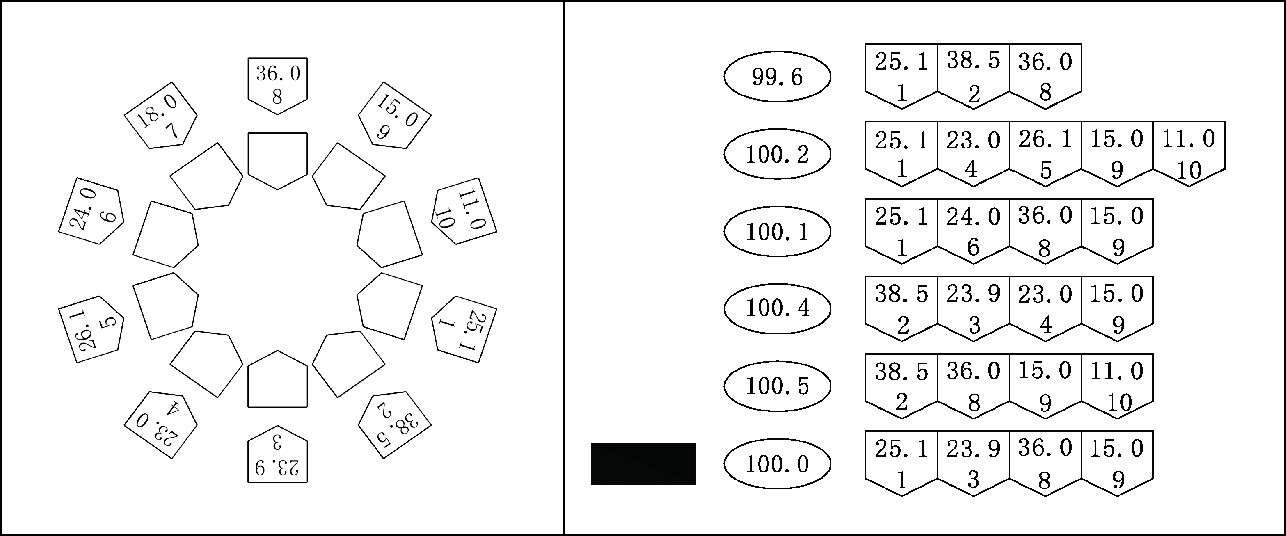

The core weighing principle of a combination weigher is based on simultaneous weighing using multiple independent weighing units, typically ranging from 8 to 32.

-

Each weighing hopper records the material weight.

-

The built-in control system compares data with the target weight.

-

An optimization algorithm selects the best combination closest to the preset value.

This method ensures packaging accuracy, reduces overweight or underweight errors, saves raw materials, and improves batch acceptance rates.

How Does a Combination Weigher Work?

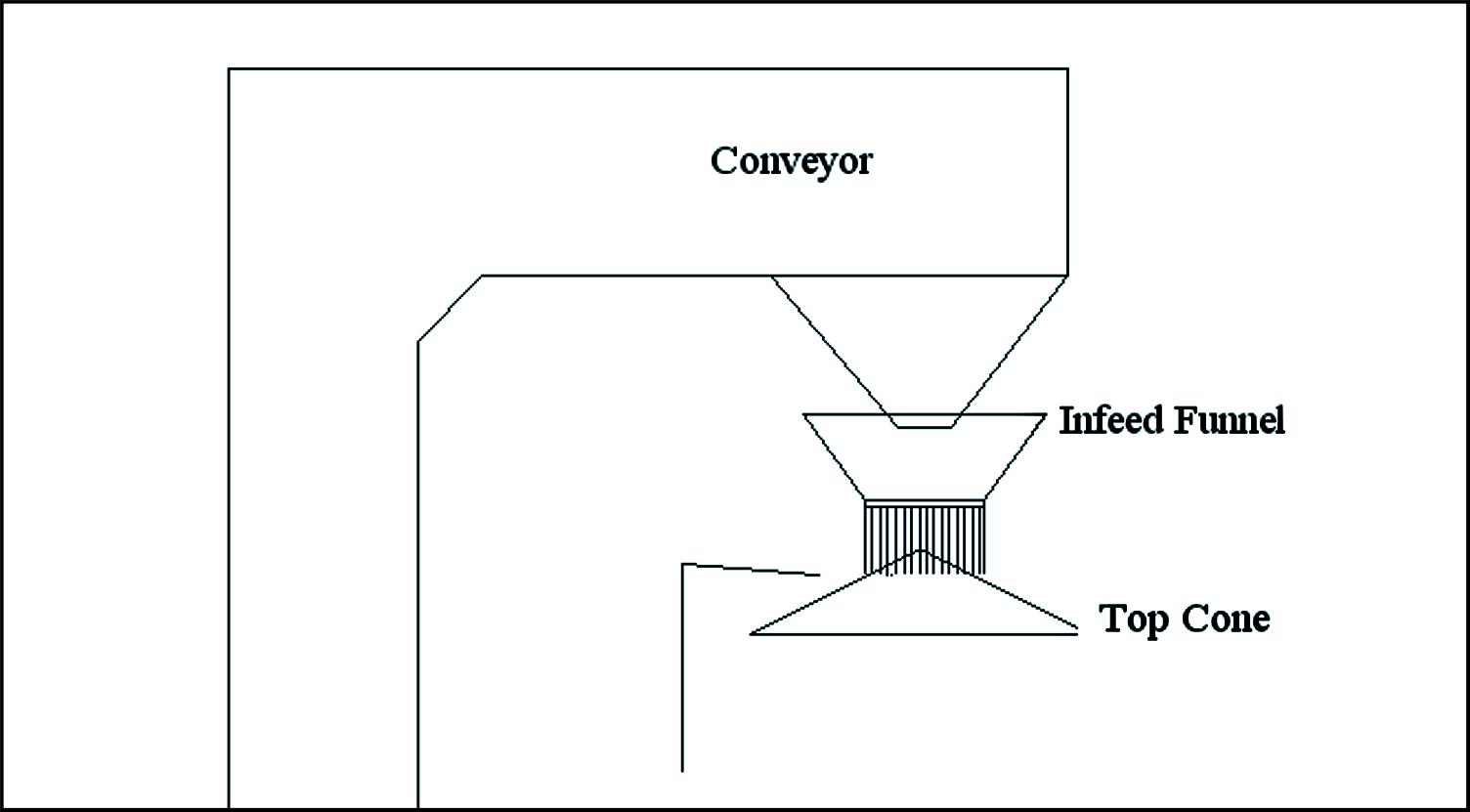

1. Feeding

Products are transferred to the infeed funnel by conveyor and evenly distributed into linear vibrator pans by the vibration of the top cone.

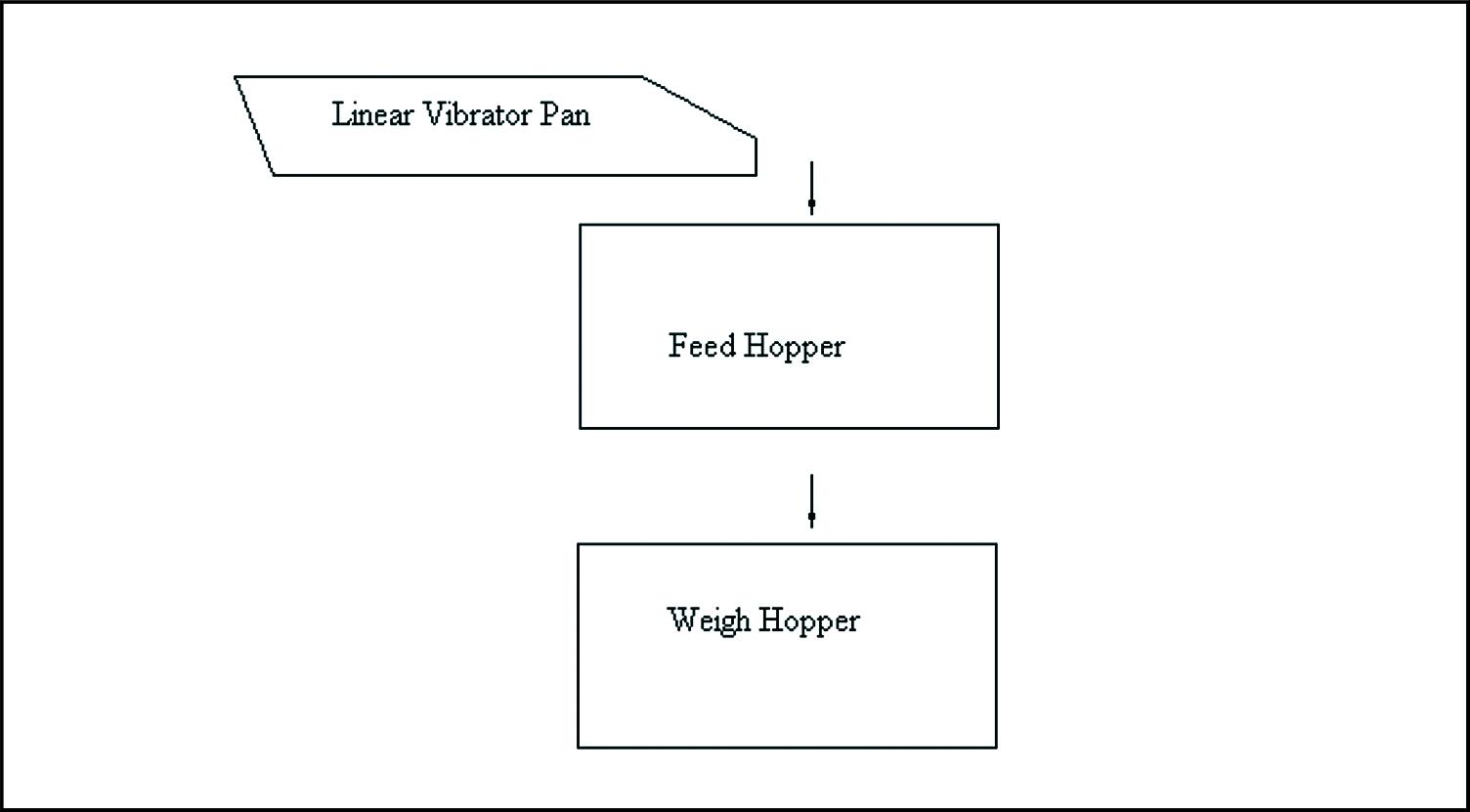

2. Distribution

From the linear vibrator pans, products drop into feed hoppers. After the weighing hopper completes the previous cycle, the feed hopper opens to release product into the weighing hopper.

3. Combination

The CPU receives data from each weighing hopper and calculates the most accurate combination according to the target weight.

4. Discharging Methods

There are four ways to discharge products into the next equipment:

-

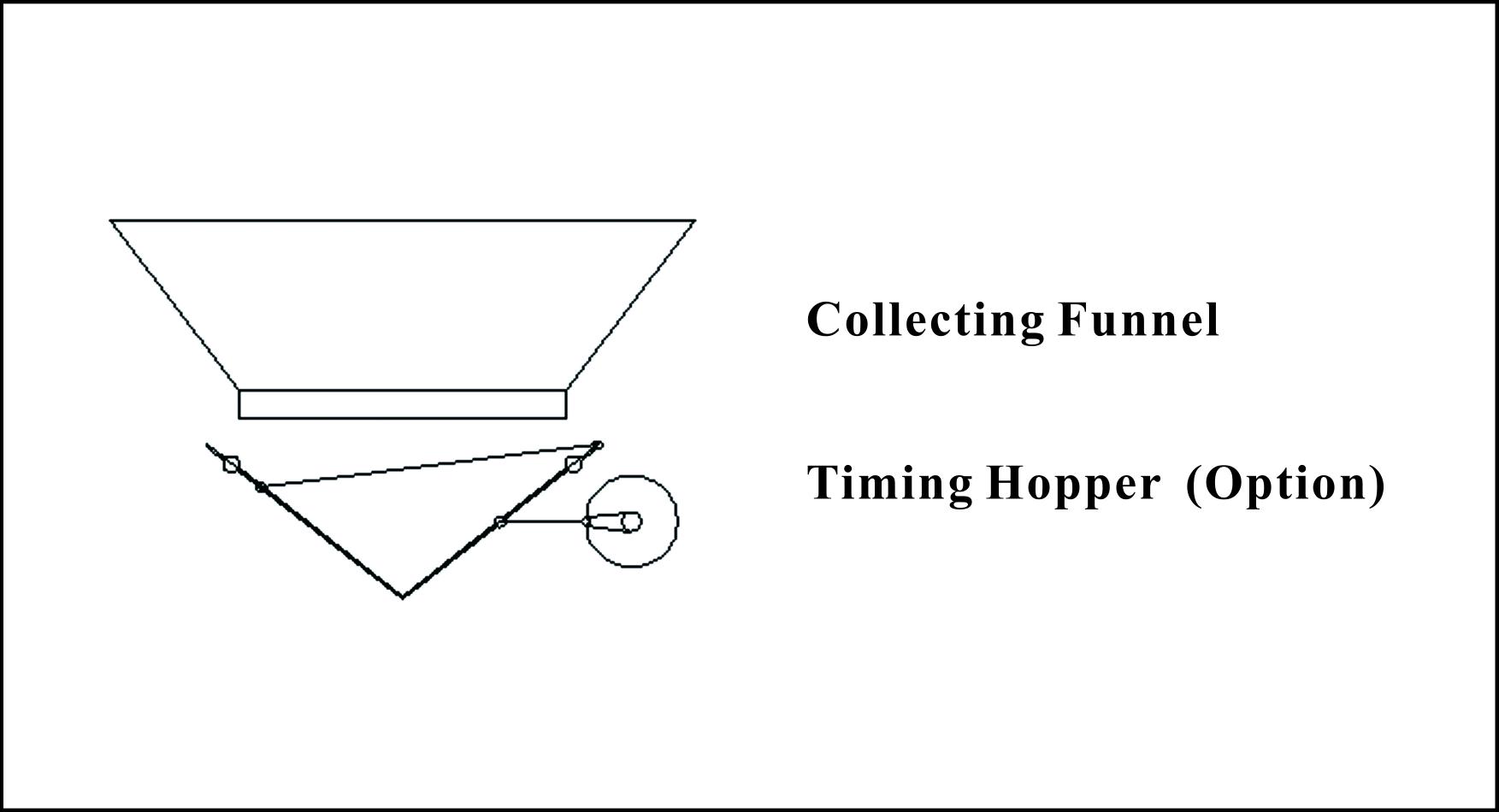

Direct Discharge (Timing Hopper = 0): Products are discharged directly from the collecting funnel.

-

Timing Hopper Discharge (Timing Hopper = 1): Products are stored in a timing hopper, then discharged to reduce drop time.

-

-

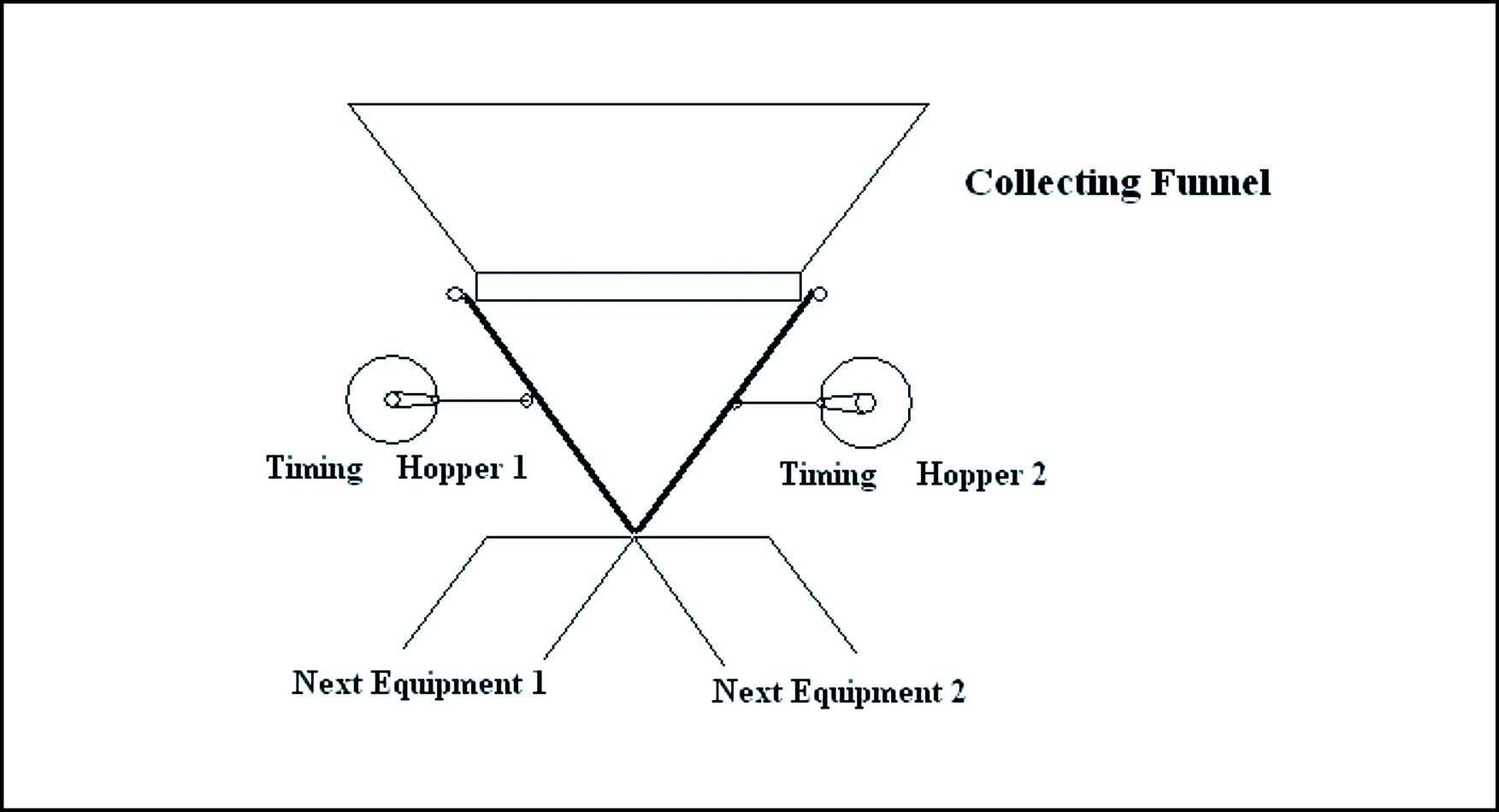

Dual Equipment Discharge (Timing Hopper = 2): Products are stored in a timing hopper, then discharged into two machines separately, maximizing high-speed output.

-

-

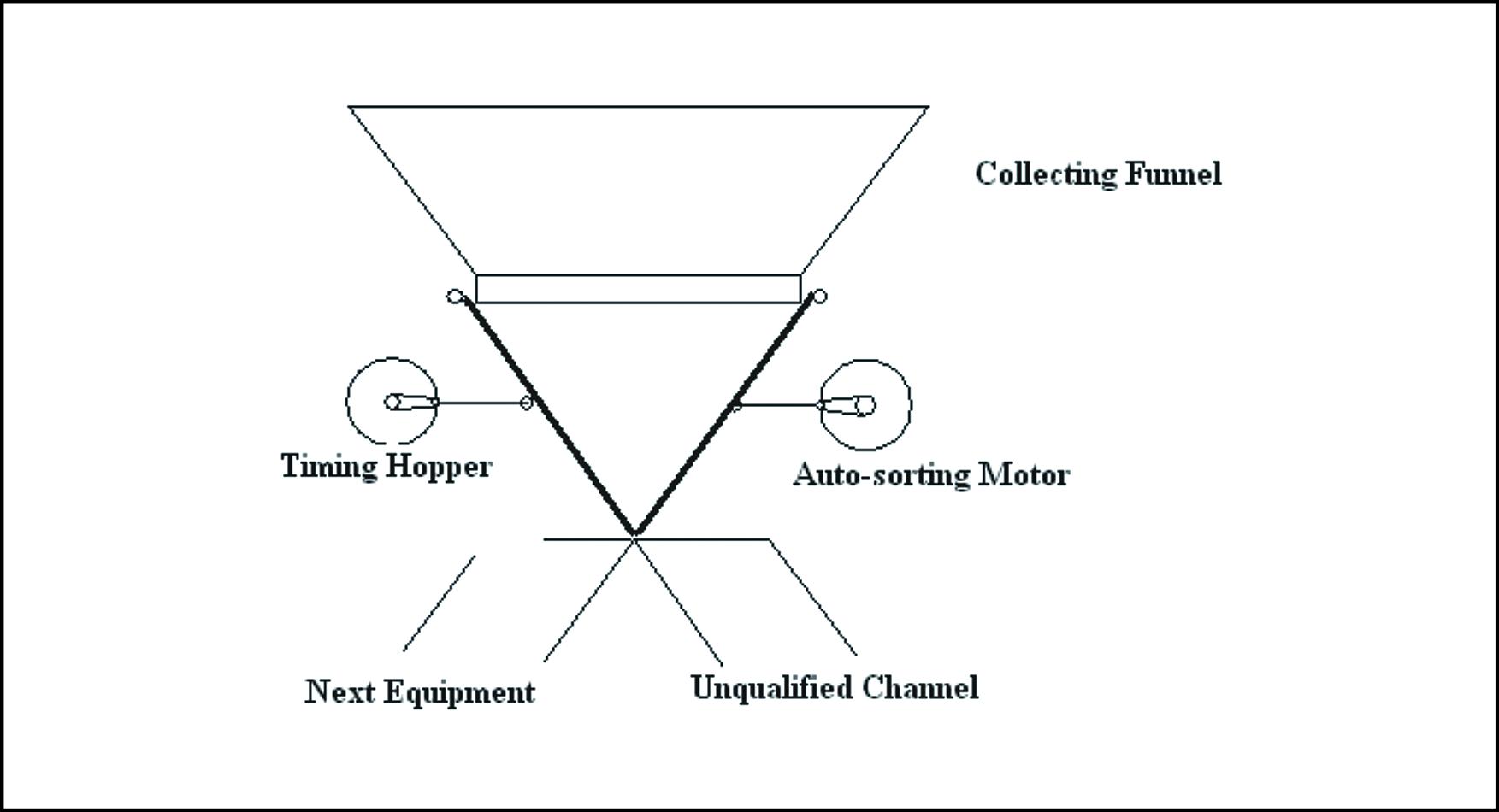

Timing Hopper + Auto-Sorting (Timing Hopper = 3): Products are stored in the timing hopper, and unqualified weights are automatically sorted into a reject channel.

-

Guangdong Kenwei – Leading Manufacturer in China

Guangdong Kenwei is one of China’s top manufacturers of combination weighers, with an annual production capacity of over 10,000 units. Its multihead weighers are widely applied in weighing and packaging of cereals, snacks, frozen foods, and other products, making it a trusted partner for global food producers.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Cooperation Process

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

The Standard Multihead Weigher features a high-speed, spring-free hopper with a new aluminum shell design, ensuring stable and fast weighing performance. The integrative welding of the mouthpiece case and middle seat enhances the overall machine strength. Ideal for weighing granular products like melon seeds, peanuts, nuts, almonds, raisins, candies, and pistachios, this 14-head multihead weigher offers hopper options of 1.6L and 2L. With a maximum weighing speed of 120 packs per minute, it delivers rapid and accurate results for high-volume operations.

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei