The Role of Multihead Weighers in Smart Packaging and Industry 4.0

- 1. Industry 4.0 and the Demand for Intelligent Weighing

- 2. Smart Multihead Weighers and Real-Time Monitoring

- 3. Predictive Maintenance for Higher Efficiency

- 4. Seamless Integration with Packaging Lines and MES/ERP Systems

- 5. Key Advantages of Intelligent Multihead Weighers

- 6. Kenwei Multihead Weighers: Designed for Industry 4.0

- 7. Applications in Industry 4.0

- 8. Conclusion

The Role of Multihead Weighers in Smart Packaging and Industry 4.0 The arrival of Industry 4.0 has fundamentally reshaped modern manufacturing. With a strong focus on automation, data-driven decision-making, and fully connected production systems, manufacturers are rethinking how packaging equipment fits into smart factory ecosystems. Within this transformation, multihead weighers have evolved from standalone weighing machines into intelligent, connected systems that play a vital role in smart packaging operations. Today, manufacturers pursuing high-speed, high-accuracy, and fully automated packaging lines are increasingly relying on advanced multihead weighers to improve efficiency, minimize product giveaway, and accelerate digital transformation. This article explores how multihead weighers support Industry 4.0 initiatives, their key technological advantages, typical applications, and why Guangdong Kenwei Intellectualized Machinery Co., Ltd. is a trusted global supplier of intelligent weighing solutions.

1. Industry 4.0 and the Demand for Intelligent Weighing

Industry 4.0—often referred to as the fourth industrial revolution—is defined by several core characteristics: Advanced automation and robotics Data-driven and real-time decision-making Interconnected systems such as IoT, MES, and ERP Predictive maintenance and AI-based optimization In packaging environments, meeting these requirements demands equipment that can communicate seamlessly, generate accurate data, and respond intelligently to changing production conditions. Multihead weighers serve as a critical foundation for this transformation, bridging precise weighing with digital connectivity.

2. Smart Multihead Weighers and Real-Time Monitoring

Modern multihead weighers integrate advanced intelligence to meet the needs of smart factories, including:

- Digital load cells combined with high-speed processors for accurate and stable combination weighing

- Real-time data monitoring to track production output, weight distribution, and operational efficiency

- Remote diagnostics and alarm systems that detect potential issues before they lead to downtime

- Automated recipe management for fast product changeovers on multi-product packaging lines

With these capabilities, multihead weighers can be seamlessly integrated into connected production systems, enabling higher productivity, improved consistency, and reduced human error.

3. Predictive Maintenance for Higher Efficiency

Predictive maintenance is a cornerstone of Industry 4.0 manufacturing strategies. Advanced multihead weighers continuously monitor critical operating parameters, such as:

- Vibration patterns and motor performance

- Feeding consistency and bucket movement

- Abnormal operating conditions

By identifying potential issues before failures occur, predictive maintenance minimizes unplanned downtime, extends equipment lifespan, and lowers overall maintenance costs. Kenwei’s intelligent multihead weighers are equipped with predictive maintenance modules, allowing operators to schedule servicing efficiently without interrupting production.

4. Seamless Integration with Packaging Lines and MES/ERP Systems

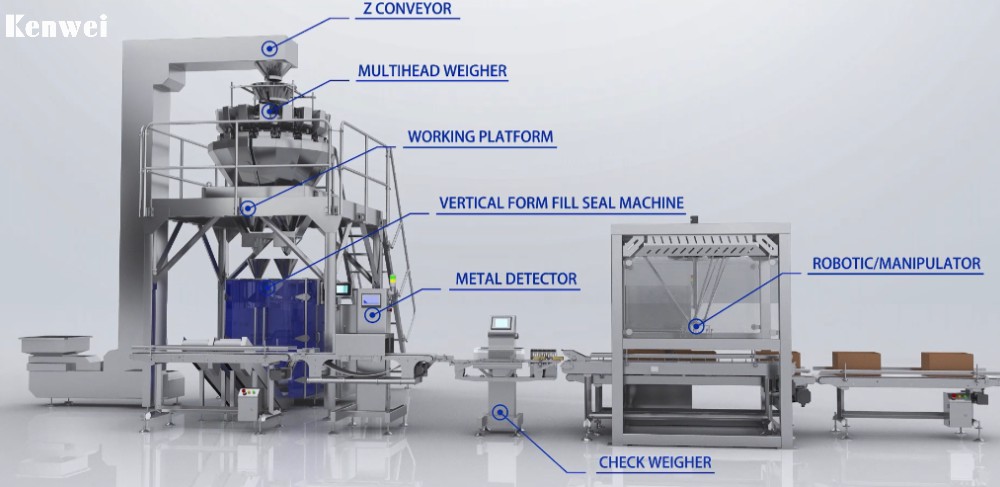

Connectivity is at the heart of Industry 4.0. Multihead weighers are designed to integrate smoothly with a wide range of packaging and control systems, including:

- Vertical Form Fill Seal (VFFS) machines

- Premade pouch packaging lines

- Checkweighers and metal detectors

- MES and ERP systems for real-time production analysis

This level of integration enables manufacturers to make immediate, data-based adjustments, maintain consistent product quality, and optimize overall throughput. Kenwei provides customized integration solutions to ensure compatibility, stable communication, and seamless workflow across the entire packaging line.

5. Key Advantages of Intelligent Multihead Weighers

1) Higher Accuracy

Real-time combination optimization minimizes product giveaway while ensuring compliance with strict weight regulations.

2) Increased Productivity

High-speed algorithms and precise bucket control support faster packaging speeds, even on high-output production lines.

3) Reduced Operational Risk

Remote monitoring, alarm notifications, and predictive maintenance significantly reduce unexpected downtime and production losses.

4) Data-Driven Decision-Making

Integrated data collection provides valuable insights into material usage, production trends, and process efficiency.

5) Operational Flexibility

Multihead weighers allow quick product changeovers with minimal downtime, making them ideal for modern multi-product facilities.

6. Kenwei Multihead Weighers: Designed for Industry 4.0

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is widely recognized for delivering multihead weighers engineered specifically for smart factory environments. Key features include:

- High-speed digital weighing with real-time optimization

- IoT-ready architecture for data collection and remote monitoring

- User-friendly HMI touchscreens for intuitive recipe and parameter management

- Durable stainless-steel construction suitable for food, pharmaceutical, and chemical applications

Kenwei’s intelligent multihead weighers help manufacturers achieve higher levels of automation, reduce waste, and enhance overall production efficiency.

7. Applications in Industry 4.0

Environments Smart multihead weighers are extensively used across a wide range of industries, including:

- Snack and confectionery production

- Frozen food processing

- Pharmaceutical tablet and capsule counting

- Hardware components and plastic granule packaging

By combining intelligent weighing with automated packaging systems, manufacturers can achieve consistent quality, high speed, and flexible production across diverse applications.

8. Conclusion

As manufacturers transition toward Industry 4.0, packaging equipment must deliver more than just precision and speed—it must also be intelligent, connected, and data-driven. Multihead weighers are at the forefront of this evolution, offering real-time monitoring, predictive maintenance, and seamless integration with automated production systems. For manufacturers seeking reliable, smart, and high-performance weighing solutions, Kenwei’s intelligent multihead weighers provide a comprehensive answer. Through innovative algorithms, robust design, and advanced digital connectivity, Kenwei helps factories meet Industry 4.0 standards while maximizing productivity, efficiency, and long-term profitability.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei