The Ultimate Guide to Vertical Packing Machines: Operation, Benefits, and Kenwei Solutions

- What is a Vertical Packing Machine?

- How Does a Vertical Packing Machine Work?

- Types of Vertical Packing Machines

- ▶ Standard Vertical Form-Fill-Seal (VFFS) Machines

- ▶ Fully Automated vs. Semi-Automated Machines

- Applications of Vertical Packing Machines

- ◆ Food Industry

- ◆ Pharmaceutical and Healthcare

- ◆ Industrial and Non-Food Packaging

- How to Choose the Right Vertical Packing Machine

- Kenwei Vertical Packing Machine Solutions

- Conclusion

Vertical packing machines have transformed modern packaging with automation, speed, and reliability. From food and pharmaceuticals to industrial products, these machines ensure precision, efficiency, and cost savings. This article explores their working principle, benefits, applications, and why Kenwei is a trusted supplier.

What is a Vertical Packing Machine?

A Vertical Packing Machine (VFFS – Vertical Form Fill Seal machine) is an automated solution that forms, fills, and seals products into bags or pouches. Using roll film and form-fill-seal technology, these machines package products vertically, ensuring high speed, precision, and cost-effective operation.

They are widely used in industries such as food, pharmaceuticals, chemicals, and hardware, handling products like powders, granules, solids, and liquids with consistency and safety.

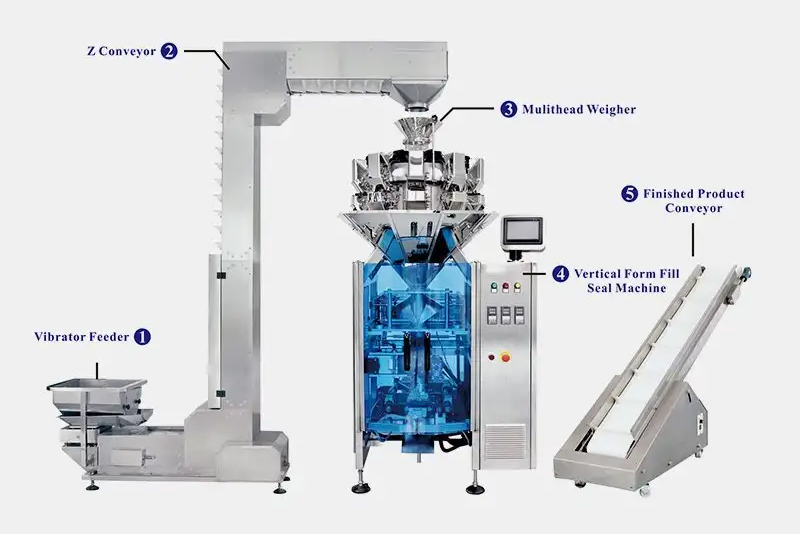

How Does a Vertical Packing Machine Work?

-

Film Feeding & Forming: A plastic film roll is fed into a forming tube, shaped into a pouch, and sealed vertically.

-

Filling Process: Products are dispensed into the formed bag via weighers or auger fillers for precise measurement.

-

Sealing & Cutting: Horizontal sealing bars close the top and bottom of each bag, completing the packaging cycle.

-

Optional Features: Gas flushing for freshness, hole punching for retail display, or custom sealing designs.

This process ensures continuous, high-speed packaging with minimal manual intervention.

Types of Vertical Packing Machines

▶ Standard Vertical Form-Fill-Seal (VFFS) Machines

The most common type, ideal for snacks, coffee, rice, sugar, and powders. They deliver consistent packaging, reduce labor costs, and maximize productivity.

▶ Fully Automated vs. Semi-Automated Machines

-

Fully Automated: Handle every process from film feeding to sealing, perfect for high-volume production lines.

-

Semi-Automated: Require partial manual input, suitable for small- to medium-sized businesses with budget constraints.

Applications of Vertical Packing Machines

Vertical packing machines are versatile and used across multiple industries:

◆ Food Industry

Perfect for packaging chips, nuts, grains, frozen foods, coffee, sugar, and flour. They ensure freshness, extend shelf life, and enable precise portioning with multihead weighers or auger fillers.

◆ Pharmaceutical and Healthcare

Used for capsules, tablets, powders, and other healthcare products. With hygienic sealing, nitrogen flushing, and desiccant insertion, they comply with strict regulatory standards.

◆ Industrial and Non-Food Packaging

Suitable for detergents, fertilizers, pet food, chemicals, and hardware. Machines support diverse packaging materials, including laminated films, polyethylene, and aluminum foil, ensuring durability and product safety.

How to Choose the Right Vertical Packing Machine

When selecting a vertical packing machine, consider:

-

Product Type: Solids, powders, or liquids.

-

Production Volume: Required daily or hourly output.

-

Packaging Materials: Compatibility with plastic, foil, or eco-friendly films.

-

Bag Styles: Pillow bags, gusseted bags, or stand-up pouches.

-

Automation Level: Fully or semi-automated.

-

Budget & Integration: Cost vs. efficiency and compatibility with existing systems.

Kenwei Vertical Packing Machine Solutions

Kenwei is a leading global supplier of packaging machinery solutions, offering:

-

Multihead Weighers

-

Linear Weighers

-

Check Weighers

-

Metal Detectors

With advanced technology, high precision, and flexible customization, Kenwei’s vertical packing machines stand out for:

-

Efficiency & Reliability: High-speed packaging with minimal downtime.

-

Versatility: Adaptable for multiple bag styles and packaging materials.

-

Customer Support: 2-year warranty, 24/7 support, and worldwide service.

Kenwei ensures optimized productivity, reduced waste, and maximum ROI, making it the trusted choice for businesses across industries.

Conclusion

Vertical packing machines are essential for modern packaging—enhancing efficiency, consistency, and versatility across industries from food to pharmaceuticals.

With its innovative technology, customizable solutions, and global support, Kenwei helps businesses streamline packaging processes and achieve long-term success.

👉 Looking to automate your packaging line? Contact Kenwei today to discover the best vertical packing machine tailored to your needs.

About Solution suggestions

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei