Compliance & Safety Features to Request in a VFFS Machine

- Compliance & Safety Features to Request in a VFFS Machine

- Why safety and regulatory compliance matter for your vertical packaging machine

- Product snapshot: Economic vertical form fill seal packing machine (VFFS)

- Key legal and regulatory frameworks to consider for any vertical packaging machine

- Essential physical safety features to request in an Economic VFFS

- Control and electrical safety requirements

- Food safety and hygienic design for packaging products

- Operational safety and human-machine interface (HMI)

- Product handling and detection systems

- Integrating multihead weighers with the VFFS: safety considerations

- Maintenance, diagnostics and risk management

- How to verify compliance at purchase and during installation

- Quick comparison: Safety features, why they matter, and recommended specs

- Brand advantages and why the Economic VFFS is a sensible choice

- How to specify safety in your purchase order (PO)

- Frequently Asked Questions (FAQ)

- Q1: What are the minimum safety devices I should expect on a VFFS?

- Q2: How do I confirm a VFFS meets CE or UL requirements?

- Q3: Will the Economic VFFS work with my multihead weigher?

- Q4: What ongoing checks should my team perform on safety devices?

- Q5: Are there add-on safety options for increased protection?

- Contact / Request a quote

- Authoritative references and further reading

Compliance & Safety Features to Request in a VFFS Machine

Why safety and regulatory compliance matter for your vertical packaging machine

When sourcing a vertical packaging machine — commonly described as a vertical packaging machine or VFFS (vertical form fill seal) — safety and compliance are not optional. They protect workers, reduce downtime, avoid costly recalls, and preserve regulatory approvals for food, pharmaceutical, and consumer goods. The right compliance features reduce legal risk and improve operational uptime and product quality.

Product snapshot: Economic vertical form fill seal packing machine (VFFS)

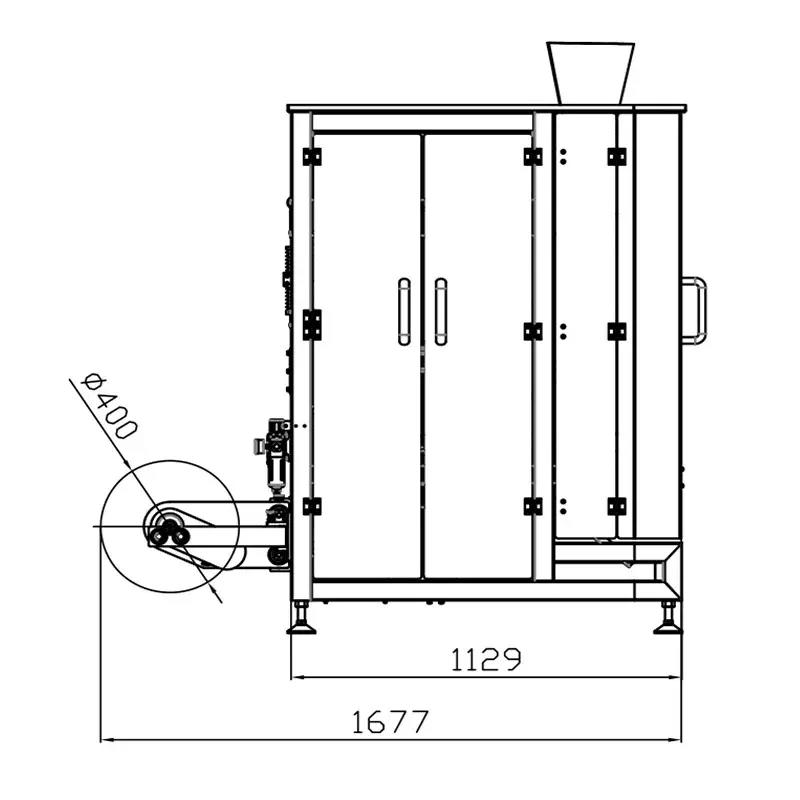

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

Key legal and regulatory frameworks to consider for any vertical packaging machine

Before specifying machine features, understand the frameworks that influence design and documentation:

- Machine safety directives and standards (e.g., EU Machinery Directive, CE marking requirements).

- International standards for machine safety and risk reduction (ISO 12100; ISO 13849 for safety-related parts of control systems).

- Electrical and electromagnetic compatibility regulations (e.g., IEC/EN standards, UL/CSA for North America).

- Food safety and hygienic design rules for materials contacting food (FDA, FSMA in the U.S.; EU food contact regulations).

- Local occupational safety and health regulations (OSHA in the U.S., local labor safety agencies elsewhere).

Essential physical safety features to request in an Economic VFFS

Physical safety elements prevent direct human contact with hazardous zones and reduce the chance of accidental injury or contamination. For the Economic vertical form fill seal packing machine (VFFS), insist on:

- Interlocked guards and safety doors: Doors on access panels should be interlocked so the machine cannot run when open. These should meet relevant PL (Performance Level) or SIL requirements depending on your risk assessment.

- Emergency stop (E-stop) stations: Redundant, tamper-proof E-stops placed at operator and maintenance positions. Ensure they are to EN ISO 13850/IEC 60204 standards.

- Non-contact safety devices: Light curtains or area scanners where guards aren’t practical (e.g., in-feed and discharge areas). These reduce nuisance trips and maintain protection for repetitive operations.

- Fixed guards and physical barriers: Mesh or plate guards for moving components (film rollers, sealing bars, gearboxes).

- Lock-out / tag-out (LOTO) points: Clear LOTO capability for electrical isolation and energy dissipation to support safe servicing.

Control and electrical safety requirements

Control systems must protect against unexpected motion, electrical faults, and software failures. Request the following:

- Safety-rated control architecture: Safety PLC or safety relay modules for E-stop, door interlocks, and light curtain signals, designed to an appropriate SIL/PL level.

- Grounding, short-circuit and overcurrent protection: Labeled, accessible circuit protection and verified grounding to reduce fire/electrocution risk.

- EMC shielding and filtering: To prevent control interference in noisy industrial environments.

- Clear wiring and documentation: Schematics, terminal labels, and a single-point-of-truth electrical manual for serviceability.

Food safety and hygienic design for packaging products

For food, frozen, and other contamination-sensitive products, hygienic design is critical:

- Food-grade materials: The Economic VFFS uses 304 stainless steel — request verification that all product-contact components meet food-contact standards and are corrosion-resistant.

- Sanitary construction: Rounded corners, minimal horizontal surfaces, and sloped frames to avoid water pooling and allow easy cleaning.

- Sealed motors and gearboxes: Motors and other drives should be IP-rated to prevent ingress and allow washdown where required.

- Cleanability and access: Guards and panels that are easy to remove without tools for washdown and inspection.

- Allergen and cross-contamination controls: Design options for quick changeovers and clean separation where multiple products are packaged on the same line.

Operational safety and human-machine interface (HMI)

The machine operator experience affects safety and productivity. Key features to request:

- Intuitive HMI with safety functions: Clear fault messages, guided troubleshooting, password protection for critical settings, and step-by-step shutdown/startup procedures.

- Training and documentation: Operator manuals, maintenance procedures, and on-site training packages from the supplier.

- Visual and audible alarms: For film faults, jam detection, low film, or unsafe conditions so operators respond quickly.

- Ergonomics: Heights, control placements, and access that reduce operator strain and manual handling risk.

Product handling and detection systems

Protect product quality and reduce waste with sensing and verification features:

- Film run detection and web guides: Automatic run-stop on film misalignment to prevent wasted film and sealing errors.

- Bag presence and seal inspection sensors: Verify seals and reject unsealed bags automatically.

- Overfill/underfill detection: Integration with check weighers or multihead weighers to ensure correct net weight and compliance with trade laws.

- Jam detection and safe restart protocols: Automatic detection with safe restart requiring reset after removing the hazard.

Integrating multihead weighers with the VFFS: safety considerations

When pairing a multihead weigher with the Economic vertical form fill seal packing machine, coordinate safety across both machines:

- Safety communication: Hardwired safety signals or safety fieldbus linking E-stops, door interlocks, and light curtains across both units so either machine’s fault stops the line.

- Guarding continuity: Guards should form continuous protection when the weigher and VFFS are adjacent. Do not leave unprotected gaps where operators could reach in between machines.

- Synchronized lockouts: LOTO procedures that isolate both machines simultaneously during service.

- Conveyor and transfer design: Gentle transfer design to avoid product bridging that can cause blockages and unsafe clearing procedures.

Maintenance, diagnostics and risk management

Request features that make safety durable and verifiable over the machine’s life:

- Built-in diagnostics and event logs: Time-stamped fault logs and maintenance reminders help demonstrate due diligence and speed troubleshooting.

- Spare parts strategy: Availability of critical safety spares (interlocks, light curtain emitters/receivers, safety relays) and clear part numbers in documentation.

- Risk assessment package: A supplier-provided risk assessment (per ISO 12100) and a machine-specific instruction manual describing foreseeable misuse and mitigation measures.

- Planned preventive and predictive maintenance: Schedule for verifying safety devices, lubrication, and electrical checks to reduce degradation-related failures.

How to verify compliance at purchase and during installation

Buying a compliant machine requires objective evidence. Ask for:

- Certificates and conformity documents: CE Declaration of Conformity (EU), UL/cUL listings (North America), and any regional approvals required for your market.

- Factory Acceptance Test (FAT): A documented FAT demonstrating safety functions, interlocks, and emergency stops work under simulated conditions.

- Site Acceptance Test (SAT) / IQ-OQ procedures: Installation Qualification and Operational Qualification scripts to prove the machine operates safely in your environment.

- Machine file and technical documentation: Electrical drawings, parts list, software versions, risk assessment, and instruction manuals in your language.

Quick comparison: Safety features, why they matter, and recommended specs

| Feature | Why it matters | Minimum spec | Recommended for Economic VFFS |

|---|---|---|---|

| Interlocked doors | Prevents access to hazardous zones while running | Positive-opening interlocks, PLc/PLd | Key or guarded interlocks with safety PLC integration |

| Light curtains / area scanners | Protects hand/arm access where guards limit operation | EN/ISO-compliant light curtain | Area scanners for variable access areas with muting/configurable zones |

| Emergency stops | Immediate shutdown on hazard | Accessible E-stops at operator points | Multiple redundant, latching E-stops with safety PLC logging |

| Hygienic frame (304 SS) | Food safety, corrosion resistance | 304 stainless steel frame | 304 SS with sanitary design and IP-rated drives |

Brand advantages and why the Economic VFFS is a sensible choice

The Economic vertical form fill seal packing machine (VFFS) balances cost-efficiency with practical safety and hygiene features. Key brand advantages to emphasize when evaluating this model:

- 304 stainless steel construction: Provides a durable, food-safe base that simplifies cleaning and long-term corrosion resistance.

- Built-in safety door protection: Reduces the need for aftermarket guarding and supports safer operation from day one.

- Supports multiple bag types: Flexibility reduces changeover time and can reduce manual handling risks during format changes.

- Affordability with reliable performance: A good option for growing operations that require compliance without High Quality cost.

- Integration-ready: Easily pairs with multihead weighers and downstream systems while providing the essential safety interfaces required for system-level compliance.

How to specify safety in your purchase order (PO)

Include clear, non-negotiable clauses in your PO and technical specification:

- Required safety standards and certification (CE, UL, ISO compliance examples).

- Mandatory FAT/SAT acceptance criteria and test scripts.

- Documentation package and language requirements.

- Warranty conditions for safety devices and lead time for spare parts.

Frequently Asked Questions (FAQ)

Q1: What are the minimum safety devices I should expect on a VFFS?

A: At minimum: interlocked doors, at least one accessible emergency stop, fixed guarding for moving parts, clearly labeled electrical isolation, and an operator manual with safe operating procedures. For food applications, 304 stainless steel and sanitary design are also minimum expectations.

Q2: How do I confirm a VFFS meets CE or UL requirements?

A: Request the Declaration of Conformity (CE) and the specific test reports or listings for UL/CSA. Confirm that the machine was tested to relevant harmonized standards listed in the declaration or the UL listing.

Q3: Will the Economic VFFS work with my multihead weigher?

A: Yes — the Economic VFFS supports integration. Ensure your supplier provides safety I/O for E-stop and interlocks, mechanical transfer design, and a FAT showing synchronized safety behavior between the weigher and the VFFS.

Q4: What ongoing checks should my team perform on safety devices?

A: Regularly test E-stops, interlocks, light curtains, and safety PLC status. Follow a preventive maintenance schedule and log tests. Replace worn guards and failed safety sensors promptly.

Q5: Are there add-on safety options for increased protection?

A: Yes. Consider area scanners, advanced safety PLCs with diagnostics, guarded access with key-transfer systems, and redundant safety circuits for mission-critical lines.

Contact / Request a quote

Meeting today’s safety requirements is important, but long-term success also depends on scalability and future-proofing your vertical packaging investment.If you'd like more details, a compliance datasheet, or to schedule a factory acceptance test for the Economic vertical form fill seal packing machine (VFFS), contact our sales team. We can provide FAT templates, risk assessment files, and integration advice for multihead weighers and other upstream equipment.

Authoritative references and further reading

The B2B Buyer’s Guide to linear weigher single head

The B2B Buyer’s Guide to 14 head multihead weigher

Multihead Weigher Buying Guide for Pickles: 14-Head Backup Specs

How 14 Heads Vertical Single-Screw Feeding Pickles Weigher backups work

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

Automatic Multi-Function Pouch Weighing and Packing Machine – 65 BagsMin for Efficient Packaging

The mini combined weighing and packaging machine integrates a miniature multi-head scale with a vertical packaging machine, all controlled by an advanced PLC program. This fully automatic system handles metering, filling, bag-making, date printing, and packaging output. Ideal for weighing small particles such as Chinese herbal medicine, tea, seeds, monosodium glutamate, chicken essence, coffee beans, chocolate, and more. With its affordable price, low maintenance costs, and high efficiency, the mini combined weighing and packaging machine is an economical choice for small-scale operations.

Mini Combined Weighing and Packing Machine with Multihead Weigher for Tea Powder, Coffee Beans, and More

The mini combined weighing and packaging machine integrates a compact multi-head scale with a vertical packaging machine, all controlled by an advanced PLC program. This fully automated system handles precise metering, filling, bag-making, date printing, and packaging output. Ideal for weighing small particles such as Chinese herbal medicine, tea, seeds, monosodium glutamate, chicken essence, coffee beans, chocolate, and more. The mini combined weighing and packaging machine is cost-effective, economical, and offers low maintenance costs, making it an excellent choice for small-scale packaging operations.

Standard Vertical Weighing And Packaging Machine For Granules Puffy Foods JW-B1

Discover Kenwei’s Standard Vertical Weighing And Packaging Machine For Granules Puffy Foods. This efficient vertical packaging machine accurately weighs and packs a variety of foods, making it the ideal weighing and packaging machine for granules and puffy snacks.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei