Industrial Control Sensors Driving Automation in China | Market Trends & Opportunities

- Sensor Applications: From Defense to Daily Life

- What Are Industrial Control Sensors?

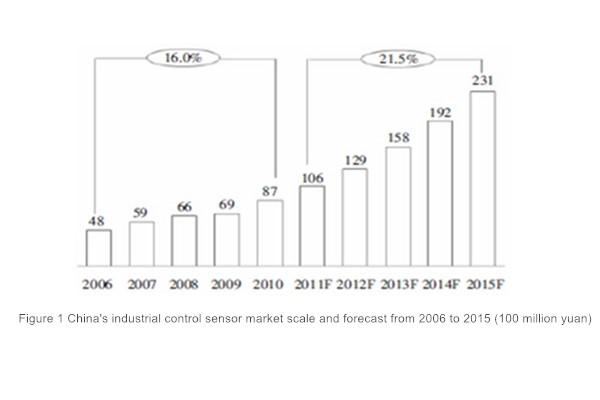

- Market Outlook: Rapid Growth Fueled by Policy and Demand

- Market Segmentation: Leading Sensor Categories in China

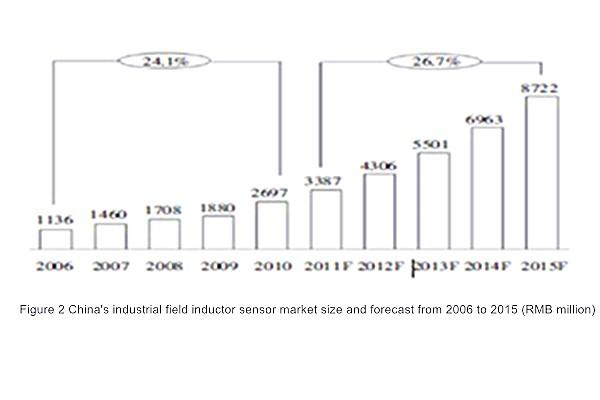

- 1. Inductive Sensors

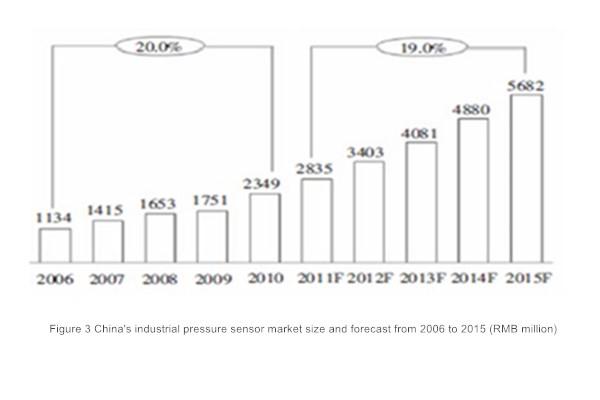

- 2. Pressure Sensors

- 3. Photoelectric Sensors

- 4. Capacitive Sensors

- Conclusion: The Smart Sensor Future

Explore the booming market of industrial control sensors in China—covering inductive, pressure, photoelectric, and capacitive sensors fueling automation.

As the global manufacturing industry rapidly embraces automation, industrial control sensors have become the backbone of intelligent, efficient, and responsive production systems. From machinery and chemical plants to advanced packaging solutions, sensors enable real-time detection, feedback, and precision control.

China, in particular, has witnessed exponential growth in its sensor market, driven by industrial upgrading, policy support, and rising demand for automation technologies across diverse sectors.

Sensor Applications: From Defense to Daily Life

While sensors were initially developed for military purposes, their applications have expanded into two major categories: industrial control and end-user products.

-

Industrial control sensors are extensively used in sectors like machinery manufacturing, metallurgy, energy, electronics, textiles, food processing, pharmaceuticals, and tobacco.

-

End-product sensors are widely embedded in automotive electronics, smart appliances, communication devices, and various forms of special equipment.

Among these, industrial control sensors play a pivotal role in automating production processes and ensuring precision in complex manufacturing environments.

What Are Industrial Control Sensors?

Industrial control sensors are specialized devices used to monitor and control variables such as displacement, pressure, flow, vibration, temperature, and position in automated systems. Key types include:

-

Inductive Sensors

-

Pressure Sensors

-

Photoelectric Sensors

-

Capacitive Sensors

Each category offers unique advantages for specific industrial applications, contributing to smarter, safer, and more efficient production systems.

Market Outlook: Rapid Growth Fueled by Policy and Demand

Thanks to consistent economic expansion and the push for industrial modernization, China’s industrial control sensor market has experienced substantial growth.

-

In 2010, the market reached 8.7 billion RMB, up 26.1% year-over-year.

-

From 2006 to 2010, the average compound annual growth rate (CAGR) stood at 16%.

According to research by the Ministry of Industry and Information Technology (MIIT) and the Chinese Academy of Social Sciences, China entered the mid-to-late phase of industrialization during the “12th Five-Year Plan” period, marked by:

-

Development of high-end manufacturing

-

Rapid rise of emerging strategic industries

-

Emphasis on digitalization and smart manufacturing

-

Expansion of foreign investment and industrial transfers into China

These trends, coupled with state policies supporting equipment upgrades, import tax relief on key components, and integration of information systems, signal a strong growth trajectory for the automation and sensor industries.

It’s estimated that from 2011 to 2015, China’s industrial control sensor market will grow at a CAGR of 21.5%, reaching 23.1 billion RMB by 2015.

Market Segmentation: Leading Sensor Categories in China

1. Inductive Sensors

Inductive sensors detect physical changes such as displacement, pressure, and vibration using electromagnetic principles. They are highly reliable, cost-effective, and immune to harsh environments.

Applications: Widely adopted in packaging, automotive, textiles, plastics, tobacco, steel, petrochemical, and machinery manufacturing.

-

In 2010, the market size reached 2.697 billion RMB, accounting for 31% of the overall sensor market.

-

Expected CAGR (2011–2015): 26.7%

2. Pressure Sensors

Pressure sensors convert physical pressure into electrical signals. Common types include piezoresistive, capacitive, and fiber-optic sensors. Piezoresistive sensors dominate due to their high accuracy and affordability.

Applications: Used in industries such as aerospace, water conservancy, rail transportation, smart buildings, and oil & gas.

-

2010 Market Size: 2.349 billion RMB

-

2006–2010 CAGR: 20.0%

3. Photoelectric Sensors

Photoelectric sensors use light to detect the presence, position, or distance of objects—ideal for non-contact measurement and long-distance detection.

Applications: Logistics, semiconductor manufacturing, elevators, textiles, machinery, and packaging automation.

At companies like Guangdong Kenwei, photoelectric sensors are widely integrated into multihead weighers, checkweighers, metal detectors, and robotic pick-and-place machines—playing a key role in enhancing accuracy and reducing human error.

-

2010 Market Size: 1.74 billion RMB

-

2006–2010 CAGR: 19.8%

4. Capacitive Sensors

Capacitive sensors convert physical properties (e.g., displacement, liquid level, pressure) into changes in capacitance. They are valued for their small size, high sensitivity, and non-contact capabilities.

Applications: Used in precision measurements for vibration, pressure, and flow in electronics, automation, and biomedical equipment.

-

2010 Market Size: 609 million RMB

-

2006–2010 CAGR: 21.9%

Conclusion: The Smart Sensor Future

The rise of smart manufacturing, driven by automation, digitalization, and policy support, is propelling China's industrial control sensor market into a new era.

Companies like Kenwei are leveraging this opportunity by incorporating cutting-edge sensor technologies into their packaging machinery solutions—helping manufacturers achieve greater efficiency, precision, and scalability.

As China continues to lead in industrial transformation, industrial control sensors will remain critical to enabling the smart factories of the future.

Contact Kenwei today to explore how intelligent sensor integration can upgrade your packaging systems and boost your production efficiency.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei