Kenwei Multihead Weigher Packing Machine

Product Overview

The Kenwei multihead weigher packing machine is a reliable solution for fast, accurate portioning and packing across snacks, frozen foods, nuts, confectionery, and more. As a leading manufacturer based in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Kenwei combines experienced engineering with advanced production to deliver multi-head weighers that emphasize high speed and high precision.

Key Features

- High-speed multihead weighing for consistent throughput.

- High precision to reduce giveaway and material waste.

- Seamless integration with metal detectors, linear weighers, and check weighers for a complete line solution.

- Customizable configurations to meet product-specific requirements.

- User-friendly controls and easy cleaning for minimal downtime.

Benefits and Practical Value

Choosing a Kenwei multihead weigher packing machine delivers measurable benefits: faster production cycles, improved accuracy that protects margins, and reduced labor costs through automation. Our multi-head weighers are engineered to adapt to changes in product size and packaging types, improving line flexibility and accelerating return on investment.

One-Stop Automated Solutions & Service

Kenwei provides one-stop automated weighing and packaging solutions including design, manufacturing, installation, technical training, and after-sales support. We work closely with clients to tailor systems that match capacity, product characteristics, and layout constraints. Complementary equipment such as metal detectors, linear weighers, and check weighers can be integrated for full-line quality control.

Trust & Expertise

With robust R&D and manufacturing capabilities, Kenwei upholds stringent quality control and responsive service. Our team is committed to practical, easy-to-use machinery that helps customers scale production while maintaining product quality. For inquiries, customization, or site visits, visit our website at https://www.kenweigroup.com/ or contact our Guangdong facility.

Kenwei’s vision is to become the world's leading weighing packing machine manufacturer—delivering dependable, efficient, and precise multihead weigher packing machines that put customer needs first.

Picture Show

Qualification Certificate

CE Parallel Manipulator

Specialized, Specialized and New Small and Medium-sized Enterprises

Mixing weighing method and mixing equipment - patent certificate

Frequently Asked Questions

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

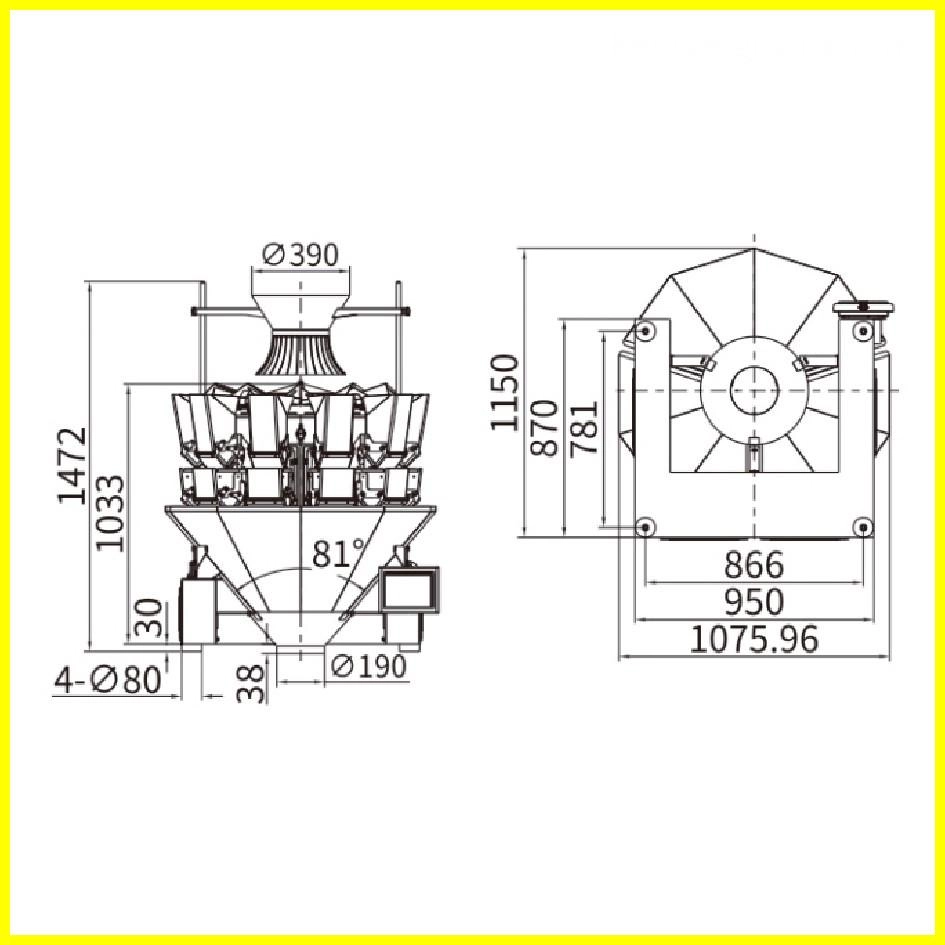

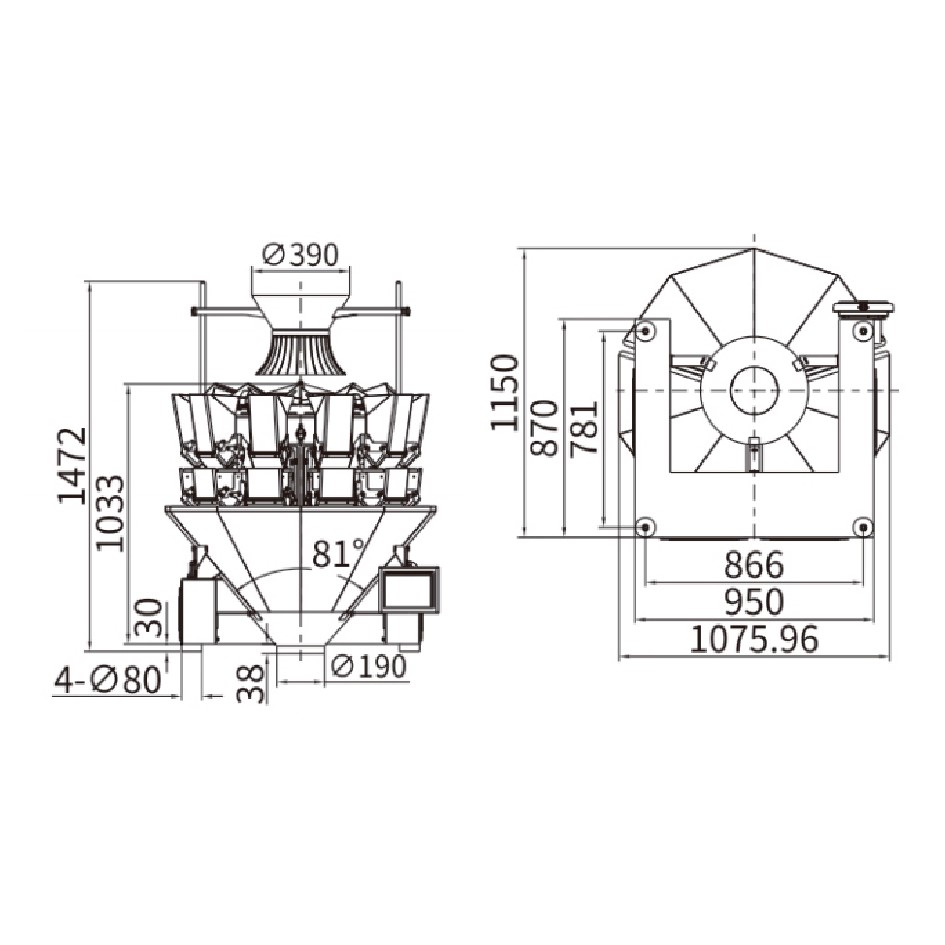

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

14 Head Multihead Weigher Packaging Machine for Weighing and Packaging Dumplings Wontons

The weighing sensor has high-precision, high-standard professional performance and adopts intelligent multi-sampling stable mode to significantly improve weighing accuracy. It also has an intelligent fault alarm function, making maintenance more efficient and convenient. The equipment supports high-speed wrong material unloading, effectively avoiding material blockage. The overall structure adopts a highly integrated modular design, integrates CAN bus technology, and applies Modbus industrial standard communication protocol to achieve seamless integration of the combined weighing system and the packaging machine.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei