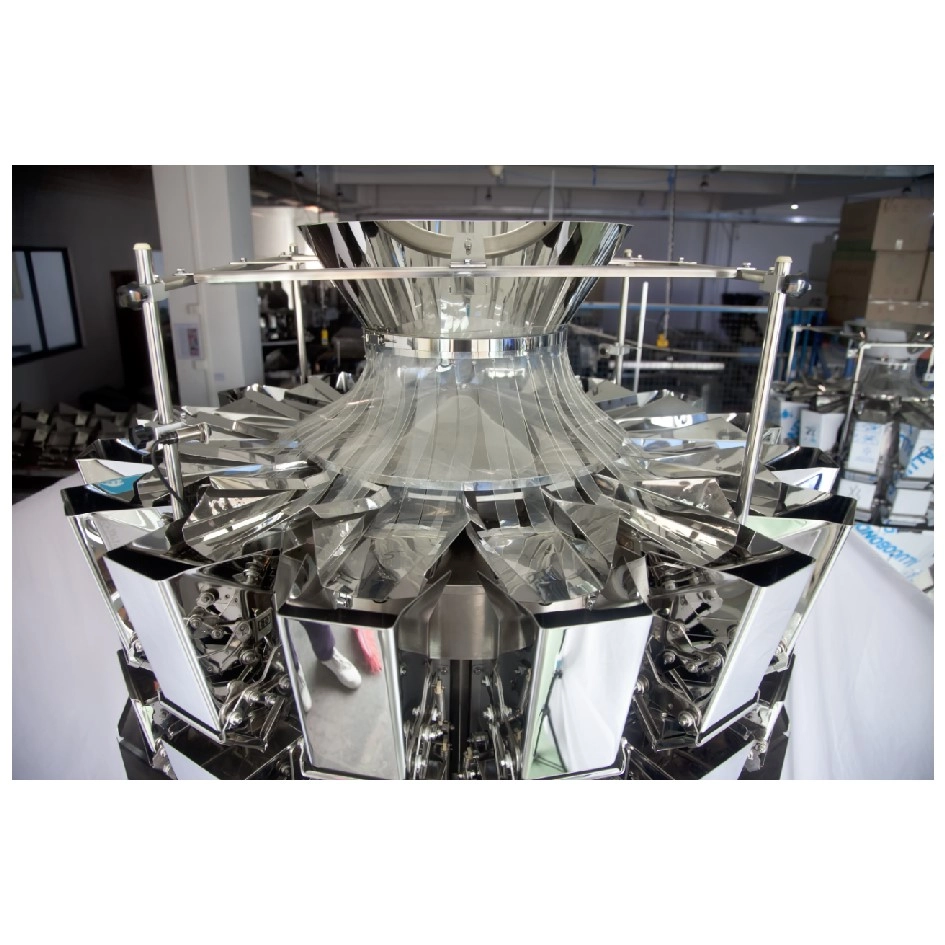

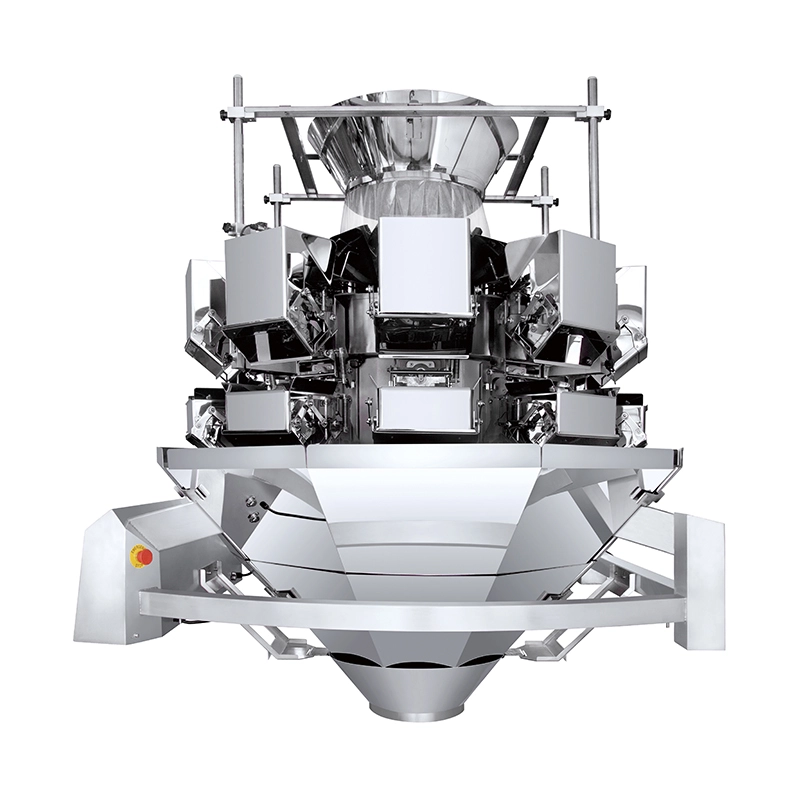

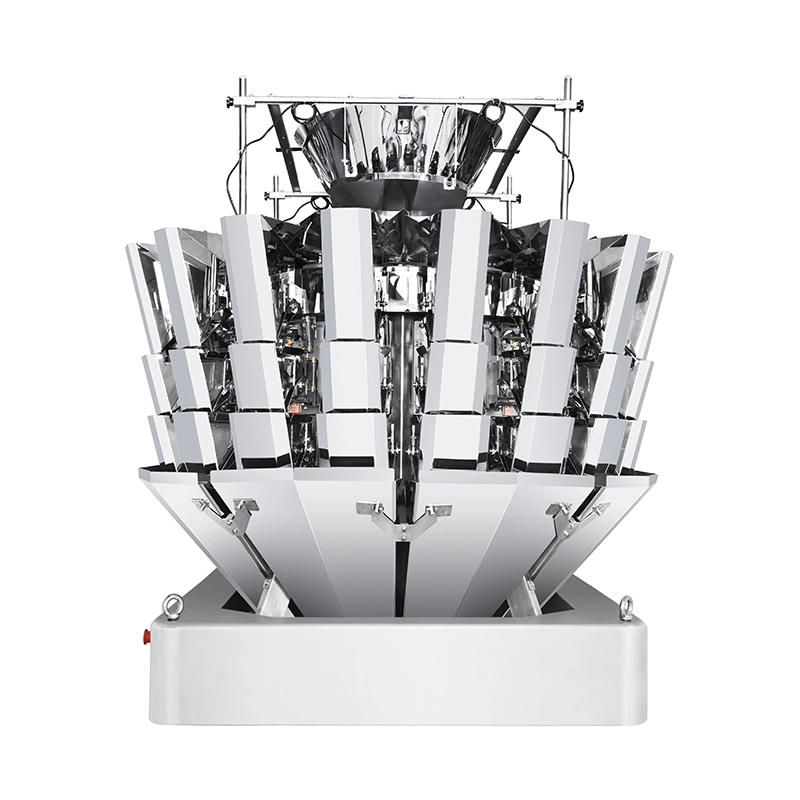

16-Head High-Speed Multihead Weigher with Dual-Layer Discharge Chute for Enhanced Efficiency

The 16-Head High-Speed Multihead Weigher with a Dual-Layer Discharge Chute is designed for maximum efficiency in fast-paced packaging environments. With a speed of up to 180 packs per minute, it handles a wide range of products, including granular, flake, strip, and irregular materials.The dual-layer discharge chute ensures smooth and continuous feeding, overcoming typical speed limitations and improving productivity. Ideal for puffed products, hardware, and bulk materials, this weigher ensures accurate, high-speed weighing with reduced waste, making it perfect for food processing and snack production lines.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 500 sets/year |

Feature

● High-Precision Special Load Cell: Designed to meet the highest standards for accuracy and reliability.

● Intelligent Multi-Sampling Stable Mode: Enhances weighing precision by continuously monitoring and adjusting for optimal results.

● Advanced Intelligent Alarm Diagnosis: Automatically detects and alerts for potential issues, minimizing downtime and ensuring smooth operation.

● High-Speed Staggered Dump Function: Ensures faster and more efficient material discharge, improving overall system speed and performance.

● Modular Design with CAN Bus Technology: Promotes greater efficiency, stability, and ease of maintenance, ensuring long-term operational reliability.

● Modbus Industry Communication Protocol: Seamlessly integrates with other machines and systems, providing flexible and standardized communication for smoother operations.

Mechanical Character

Technical Specification

| Model |

JW-AS16 |

JW-A16 |

| Identify Code |

AS16-2-7 |

A16-2-7 |

| Weighing Range |

10~200g |

10~1000g |

| Accuracy*1 |

X(0.5) |

X(0.5) |

| Max Speed*2 |

180P/M |

160P/M |

| Hopper Volume |

0.5L |

2.5L |

| Control Panel |

10.1" Touch Screen |

|

| Options |

Dimple Plate/Timing Hopper/Printer/Reject Device |

|

| Driving System |

Step Motor |

|

| Power Requirement |

220V / 1500W / 50/60Hz / 7A |

220V / 2000W / 50/60Hz / 9A |

| Packing Dimension(mm) |

1250(L)x1070(W)x960(H) |

1860(L)x1200(W)x1450(H) |

| Gross Weight |

300kg |

500 kg |

| *1: Can refer to the national standard GB/T27738-2011 or the international Legal Organization No.61 International Recommendation OIML R61 2004(E) | ||

| *2: Depends on product shape, product density, target weight, etc | ||

Application

It is ideal for packaging a wide range of materials, including melon seeds, peanuts, nuts, almonds, raisins, candies, pistachios, potato chips, shrimp sticks, dumplings, meatballs, and other granular, flake, strip, round, and irregular items. It is also suitable for the quantitative weighing and packaging of puffed foods, hardware, and various other materials.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

About After Sales Support

How about the after-sales service?

Warranty :2 years

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

Precision Leak-Proof Multihead Weigher with 3L Hopper for Accurate Small Particle Weighing

24-Head Multihead Weigher with Memory Bucket for Accurate Weighing

High-Precision 10/14 Head Multihead Weigher for Tea and Snack Food Packaging

High Precision 3-Layer 18-Head Standard Weigher for Accurate and Efficient Weighing

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei