Revolutionizing Packaging: The Power of the Weighing Packing Machine

In today's fast-paced manufacturing and processing industries, efficiency and accuracy are paramount. One key area where businesses are constantly seeking improvement is in their packaging processes. The introduction of the automatic weighing packing machine has revolutionized how businesses handle materials, offering speed, precision, and versatility that manual methods simply cannot match.

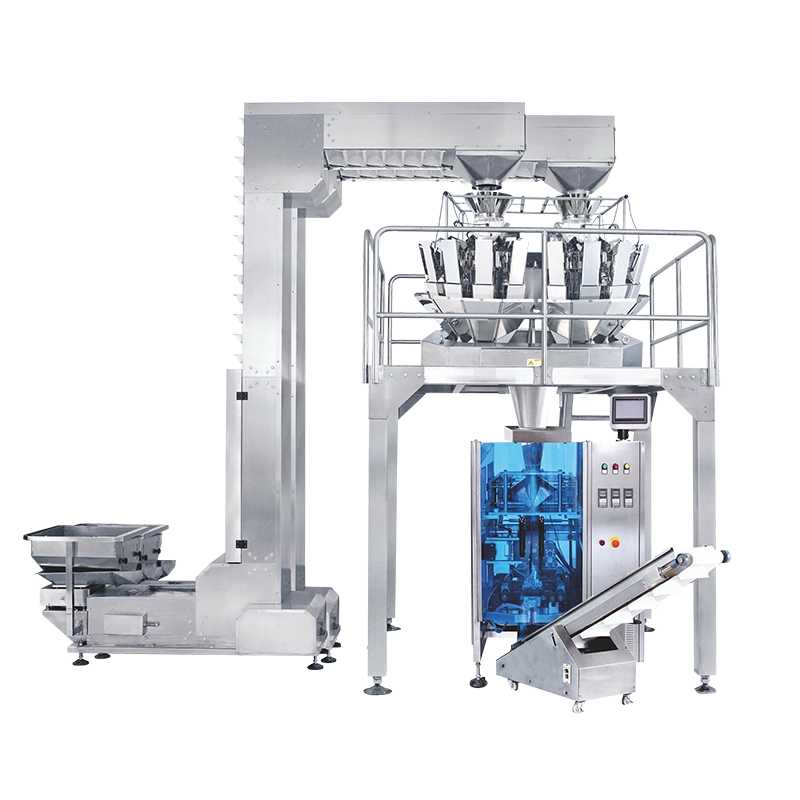

The weighing packing machine showcased in the video represents a significant advancement in packaging technology. It's designed to automate the entire process of weighing, filling, and sealing products, eliminating the need for manual labor and significantly increasing production speed. The video demonstrates a system that begins with an operator loading the raw material, such as a powder or granular substance, into a hopper. This hopper then feeds the material into a sophisticated weighing system, ensuring precise measurements for each package.

One of the most significant advantages of the weighing packing machine is its accuracy. Traditional manual weighing methods are prone to human error, which can lead to inconsistencies in product quantities and potential losses for the business. The automated system utilizes advanced sensors and controls to guarantee that each package contains the exact specified weight, minimizing waste and maximizing profitability. This precision is crucial for industries where regulatory compliance and customer satisfaction depend on consistent product quantities.

The efficiency gains offered by this machine are also substantial. By automating the weighing and packing process, businesses can significantly reduce their labor costs and increase their output. The machine can operate continuously, handling a large volume of products in a fraction of the time it would take using manual methods. This increased throughput allows businesses to meet growing demand and expand their operations without incurring excessive labor expenses.

Another notable feature of the weighing packing machine is its versatility. It can handle a wide range of materials, including powders, granules, liquids, and even small solid objects. The machine can also be adapted to different packaging formats, such as bags, pouches, and containers, making it a flexible solution for various industries. Whether you're packaging food products, pharmaceuticals, chemicals, or hardware components, a weighing packing machine can be customized to meet your specific needs.

Furthermore, modern weighing packing machines come equipped with user-friendly interfaces and advanced control systems. Operators can easily program the machine to adjust parameters such as weight, speed, and sealing temperature. The machines also incorporate safety features to protect workers and prevent accidents. Regular maintenance and cleaning are essential to ensure the machine's longevity and optimal performance. With proper care, a weighing packing machine can provide years of reliable service, delivering a strong return on investment.

In conclusion, the automated weighing packing machine is a game-changer for businesses looking to improve their packaging processes. Its accuracy, efficiency, and versatility make it an essential tool for a wide range of industries. By investing in this technology, businesses can reduce costs, increase output, and ensure consistent product quality, ultimately gaining a competitive edge in the market. As the demand for packaged goods continues to grow, the weighing packing machine will undoubtedly play an increasingly important role in the future of manufacturing and distribution.

Kenwei 2025 Annual Gala Highlights | Unite for Transformation · Empower the Future with Intelligence

Peanut Vertical Weighing and Packing Solution

Efficient Weighing and Packaging Solution for Small-Pack Pork Jerky

A smart weighing and packaging solution for soft gummy candies.

Automated Fresh Shrimp Packaging with 14-Head Multihead Weigher

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

About Cooperation Process

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Single Multihead Weigher Mixing And Weighing Packaging System For Weighing Packaging Mixing Materials JW-B26

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

Combined weighing and powder packing machine with vacuum feeder JW-B6

The system includes a vacuum feeder, multihead weigher, and vertical packaging machine.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei