Intelligent Combination Scale Weighing System for Uneven Materials | High Precision & Efficiency

This article explores an advanced intelligent combination scale weighing system designed to address challenges in weighing uneven materials. By using a high-precision load cell, a high-resolution A/D converter, and fast digital filtering algorithms, this system ensures improved accuracy and efficiency in dynamic weighing processes, benefiting food and pharmaceutical industries.

Introduction

With the rapid evolution of science and technology, the demand for precise and efficient weighing systems in the industrial sector has surged. The traditional combination scales often struggle with uneven materials, leading to inaccurate measurements and delays in packaging processes. In response, an innovative intelligent combination scale weighing system has been developed to improve precision and efficiency, making it suitable for dynamic and uneven material weighing in industrial applications.

System Design

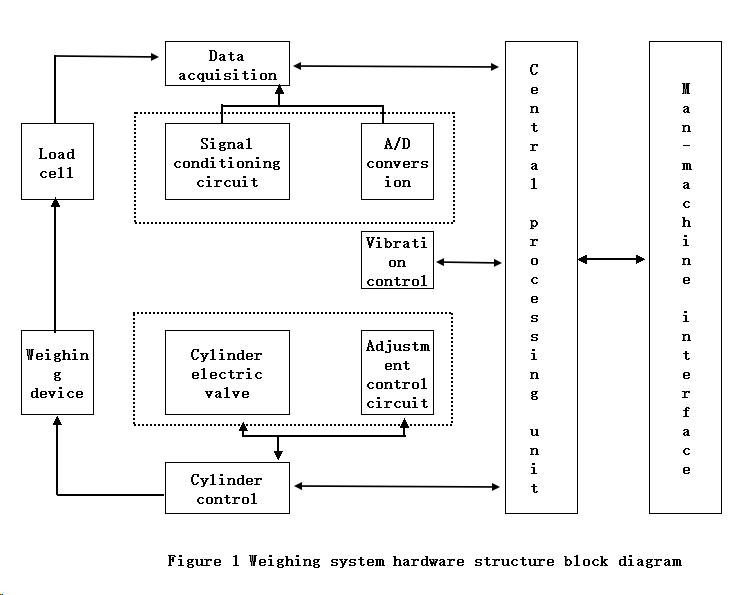

The new intelligent weighing system consists of five major components: the central processing unit (CPU), vibration control, cylinder control, data acquisition, and the human-machine interface. Each component works in sync to provide real-time, accurate measurements and to optimize the entire weighing process.

-

Central Processing Unit

The system uses a 32-bit ARM processor that acts as the control hub for data acquisition and interaction with other parts of the system. It processes signals from the load cells and controls the vibration motor and cylinder adjustment to ensure precise material delivery and weighing. -

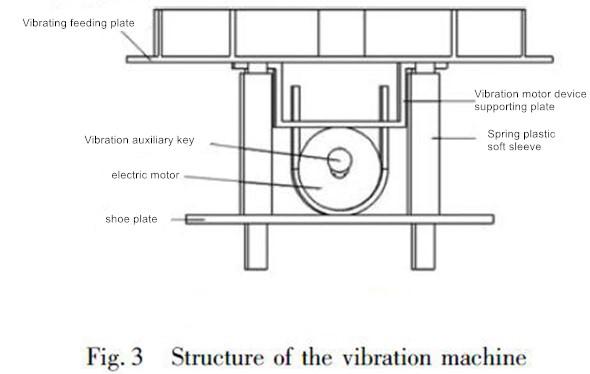

Vibration Control

A non-contact photoelectric detection switch monitors the material flow, adjusting the vibration motor’s amplitude to control the material supply to the weighing hopper, ensuring consistent feeding and accurate measurements. -

Cylinder Control

The cylinder control mechanism is responsible for opening and closing the hopper doors, allowing materials to move accurately through the system. This ensures that only the required amount of material is weighed and added to the packaging machine. -

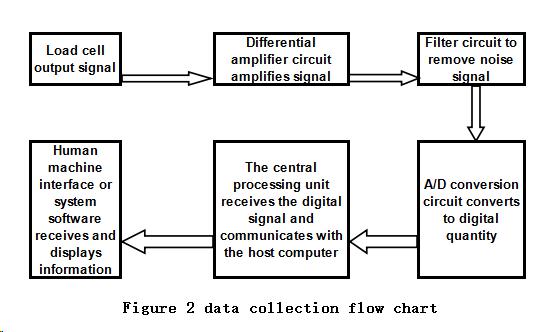

Data Collection

The load cells measure the material's weight, which is processed by the central unit. The data is then combined and calculated to determine the most accurate combination scale solution. The system utilizes magnetic shielding to eliminate interference from the vibrating equipment, ensuring high-precision data collection.

-

Human-Machine Interface

The weighing system is controlled through a user-friendly touch-screen interface. The operator can monitor real-time weight data, adjust vibration settings, and access system parameters for maintenance and calibration.

Weighing Mechanism and Structure

The intelligent weighing system uses a vibration feeding mechanism with a combination scale that can handle uneven materials efficiently. The system’s hopper holds the materials, and the combination scale mechanism ensures accurate weight distribution. After each cycle, the system pushes the material to the discharge hopper for packaging, ensuring a smooth and continuous operation.

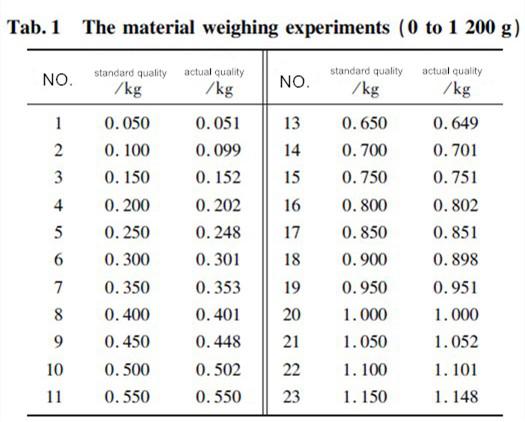

Test Results

Through testing and analysis of uneven material weighing data, the system demonstrated an accuracy of 0.5‰, achieving a high level of precision. The results showed a good correlation between the standard and actual weights, confirming the system’s efficiency in handling both uniform and uneven materials.

Conclusion

This intelligent combination scale weighing system offers significant improvements in accuracy and efficiency, especially in handling uneven materials. By incorporating advanced technology like high-resolution A/D converters and fast digital filtering, it can enhance the packaging process for industries like food and pharmaceuticals. The system’s high reliability, ease of use, and precision make it an invaluable tool for industrial manufacturers looking to improve production efficiency and meet quality standards.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei