Kenwei Packaging and Weighing System

The system includes: Vibrator feeder, Z bucket conveyor, Working platform, Multihead weigher, Discharge tube, Double feeder rotary packing machine.

Kenwei Packaging and Weighing System: Precision Meets Efficiency

Guangdong Kenwei Intellectualized Machinery Co., Ltd. proudly presents its advanced packaging and weighing system, purpose-built for businesses demanding both accuracy and speed. As a leading manufacturer in the industry and an innovator in multi-head weighers, Kenwei is dedicated to elevating your production line with cutting-edge technology and unparalleled reliability.

Our packaging and weighing system exemplifies Kenwei’s core values—precision, speed, and robust performance. Powered by state-of-the-art algorithms and high-grade components, our system delivers consistently accurate weighing and optimal packaging, reducing both product giveaway and costly errors. Whether you’re working with food, hardware, pharmaceuticals, or any granular material, Kenwei’s automated weighing and packaging solutions integrate seamlessly with your existing workflows.

Kenwei offers more than just machinery; we provide one-stop customized solutions to cater to your unique requirements. From consulting and design to installation, training, and after-sales support, our experienced team ensures your operations run smoothly from day one. Located in the Fusha High-tech Industrial Park, Zhongshan, our facility leverages the latest manufacturing technologies to guarantee robust, reliable, and long-lasting equipment.

Kenwei’s packaging and weighing systems are trusted by leading brands worldwide, earning a strong reputation thanks to our responsive service, technical expertise, and unwavering commitment to customer success. By choosing Kenwei, you’re investing in a transformative packaging solution that sets your business apart—delivering measurable improvements in speed, accuracy, and cost-effectiveness.

Experience the Kenwei difference—where intelligent weighing meets innovative packaging.

Picture Show

Our Certifications

Finished product converyor

Collecting table

Linear weigher

Frequently Asked Questions

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

Double inlet rotary packaging and weighing system JW-B9

The JW-B9 Double Inlet Rotary Packaging and Weighing System offers fully automatic feeding, weighing, bag filling, date printing, and output. Ideal for fluffy, irregular, or easily blocked materials, it ensures smooth, strong sealing and continuous high-speed operation. Suitable for snacks, puffed foods, hardware, and plastics, it supports seamless integration with conveyors and labelers to boost efficiency and reduce labor costs.

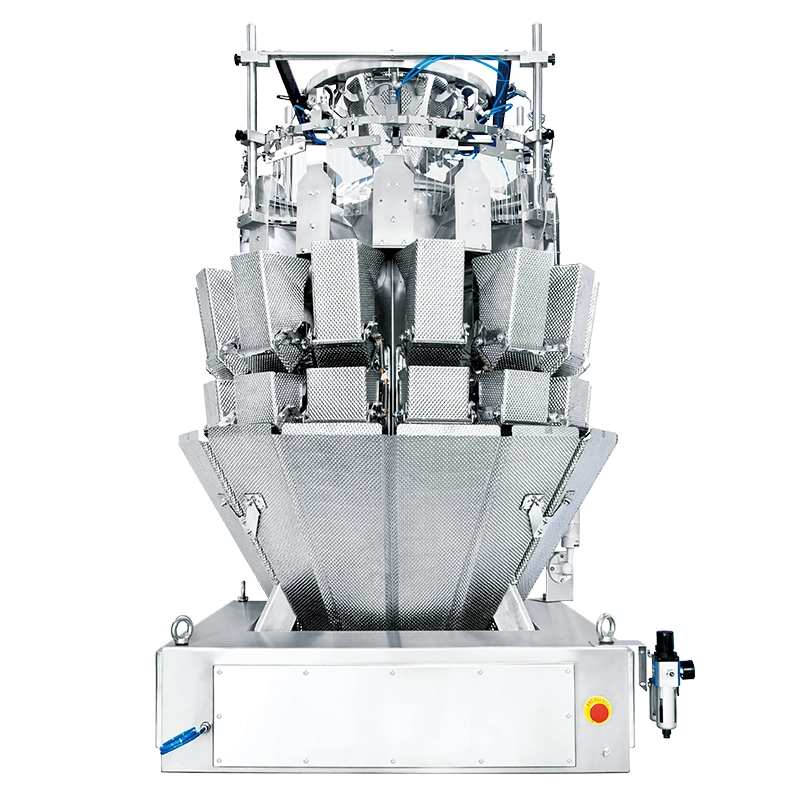

14 Heads Screw Feeding Multihead Weigher for Weighing Noodles Wakame

The Kenwei 14 Heads Screw Feeding multihead weigher offers precise, efficient weighing for noodles, wakame, and similar products. This 14-head weigher enhances productivity and accuracy, making it ideal for food processing lines seeking reliable multihead weigher solutions.

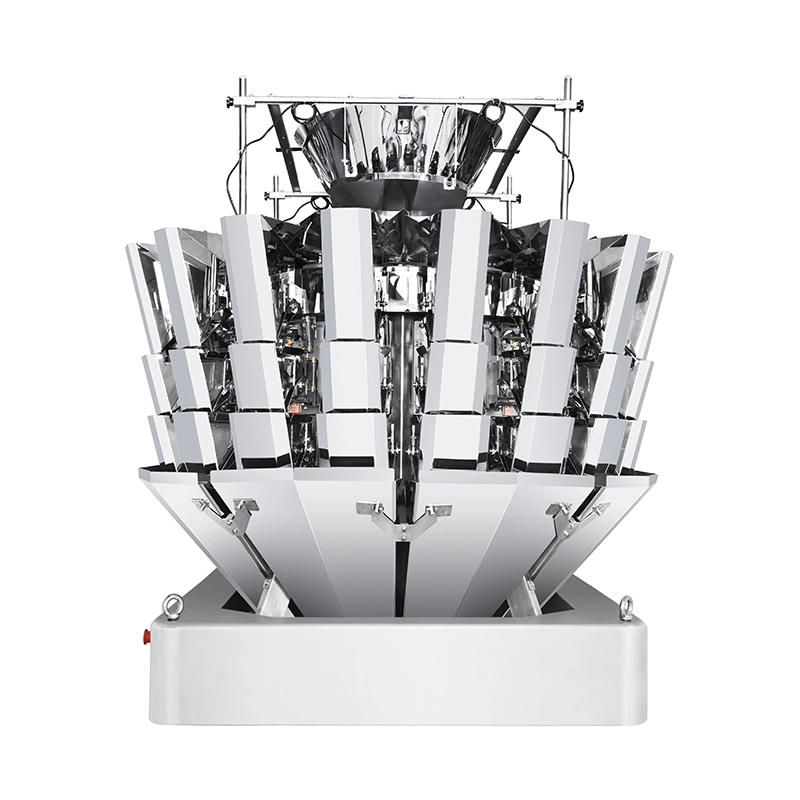

High Precision 3-Layer 18-Head Standard Weigher for Accurate and Efficient Weighing

The High-Precision 3-Layer 18-Head Standard Weigher is designed for accurate weighing of a wide range of materials, including granular, flake, round, irregular, and puffed items like nuts, seeds, candies, and snacks. It features a separate vibration plate for mixed material applications, a Ling-shaped hopper for faster and more concentrated discharge, a memory bucket for improved accuracy, and an integrated chassis for enhanced stability. Ideal for high-precision, efficient weighing.

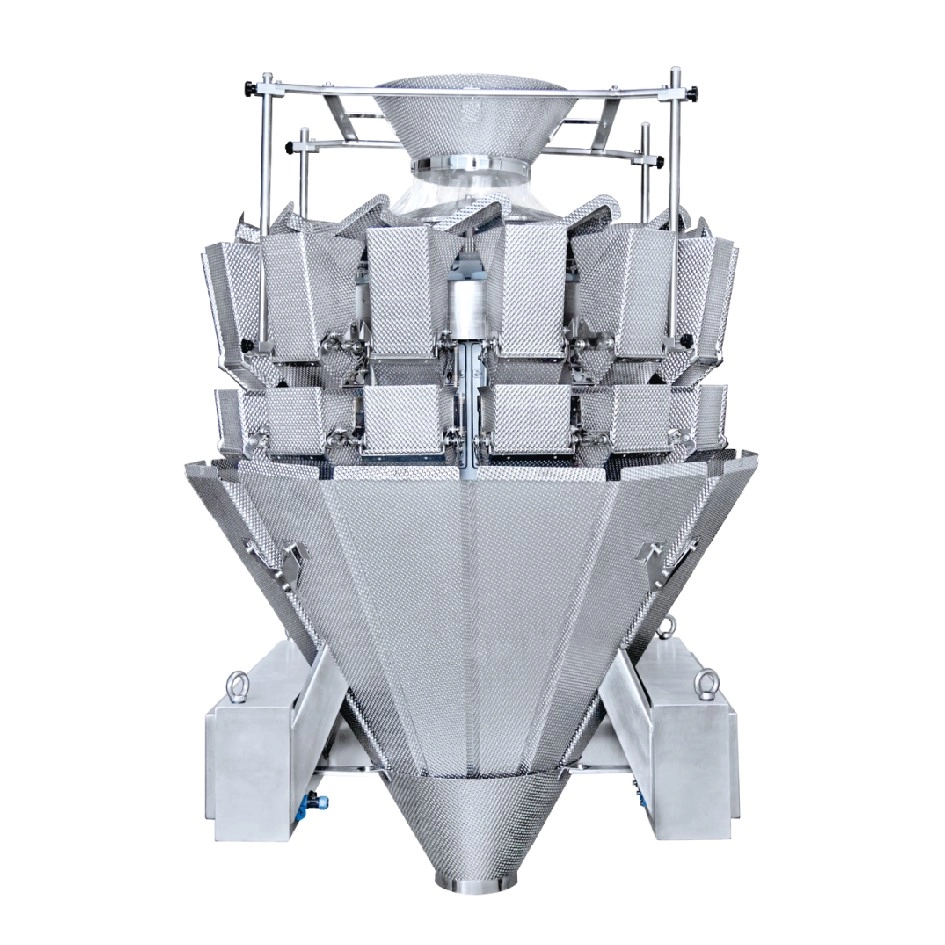

Noodle Multihead Weigher for Strip and Long Products Weighing

The Noodle Combination Weigher is designed with a pattern board material that prevents product stickiness in the hopper, making it ideal for weighing soft, long strip items like noodles. Equipped with drying and dewatering devices, this weigher also features an IP65-rated waterproof chassis, protecting the electrical components from moisture. With its advanced design, this multihead weigher guarantees consistent, high-speed performance, making it the perfect choice for efficient and accurate production lines in the food industry.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei