Kenwei Multihead Weigher: Troubleshooting Vibrator Issues for Optimal Performance

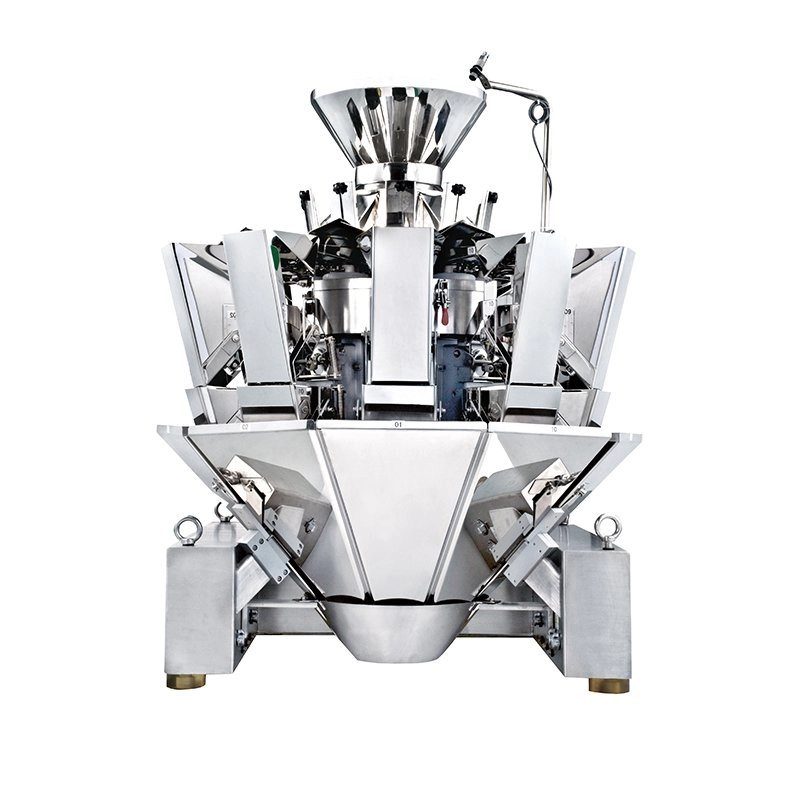

Maintaining peak performance of your multihead weigher machine is crucial for efficient packaging processes. This article, brought to you by Kenwei, delves into common issues related to vibrators in your Kenwei multihead weigher and offers practical troubleshooting steps. The focus is on addressing a scenario where one of the vibrators is not functioning correctly.

Let's consider the scenario where the No. 1 vibrator isn't operating. The video guide demonstrates a systematic approach to diagnose and rectify this issue. First, the operator accesses the machine's control panel and navigates to the manual test mode. By selecting the specific vibrator (No. 1 in this case) and activating it through the interface, the operator can immediately confirm whether the vibrator is indeed unresponsive.

If the vibrator fails to activate, the next step involves checking the machine's parameter settings. It's important to verify that the "Line Amplitude" and "Linear Time" parameters are appropriately configured. Insufficient amplitude or time settings can prevent the vibrator from functioning as intended. If these settings appear correct, the operator proceeds to the running interface to further diagnose the problem.

The control panel allows for individual amplitude adjustment. By entering this mode, the amplitude of each vibrator can be examined and modified. In some cases, a reduced amplitude setting may be the cause of the issue. However, if adjusting the amplitude doesn't resolve the problem, a deeper investigation is needed.

The video guide then directs attention to the machine's internal components. The chassis cover is opened to reveal the motherboard, the central processing unit of the multihead weigher machine. The emergency stop button is engaged to ensure safety during the inspection. One potential cause is identified as incorrect wiring, specifically an exchange of the P161 and P162 lines on the motherboard. This wiring error can disrupt the signal to the vibrator.

Another potential issue highlighted in the video is a faulty control signal from the motherboard. To test this, the operator can manually debug the system, activating another vibrator and observing its behavior. If the No. 2 vibrator does not operate when the No. 1 vibrator is triggered, it could indicate a problem with the main board's control signal. Likewise, the fuse holder of No.1 should be checked. If the fuse doesn't burn, the internal components of the motherboard may be damaged.

The guide also delves into inspecting the wiring connections and coil resistance of the vibrator itself. Loose connections or a damaged coil can prevent the vibrator from operating correctly. A multimeter is used to measure the resistance between P151 and P161. If the value between P151 and P161 is 0Ω, remove an aluminum box and find the vibration adapter plate. Measure the resistance between P151-P161 on the vibration adapter board and if the resistance value is 0Ω, if there is no contact failure, measure the coil resistance of the line vibrator. If the resistance is 0Ω, judge the coil is burnt out or the coil is open, and replace the coil. It's critical to ensure the magnet and coil have the correct gap, which is usually 4mm.

By following these troubleshooting steps, you can effectively diagnose and address vibrator issues in your Kenwei multihead weigher machine, ensuring optimal weighing accuracy and efficient operation. Remember to always prioritize safety when working with electrical equipment and consult the Kenwei user manual for further guidance.

With Kenwei's commitment to quality and innovation, our multihead weighers are engineered for reliability and performance. This troubleshooting guide underscores our dedication to providing comprehensive support and empowering our customers to maintain their equipment effectively.

Kenwei Showcases Intelligent Weighing & Packaging Solutions at Sino-Pack 2026

Kenwei 2025 Annual Gala Highlights | Unite for Transformation · Empower the Future with Intelligence

Peanut Vertical Weighing and Packing Solution

Efficient Weighing and Packaging Solution for Small-Pack Pork Jerky

A smart weighing and packaging solution for soft gummy candies.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

Leak Proof Multi Head Combination Weigher for Small Particle&Powder

Discover the Kenwei Leak Proof Multi Head Combination Weigher for Small Particle & Powder. This advanced multihead weigher machine ensures high-precision weighing, leak-proof performance, and efficiency. Ideal for various industries needing accurate combination weigher solutions.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei