Kenwei Multihead Weigher China

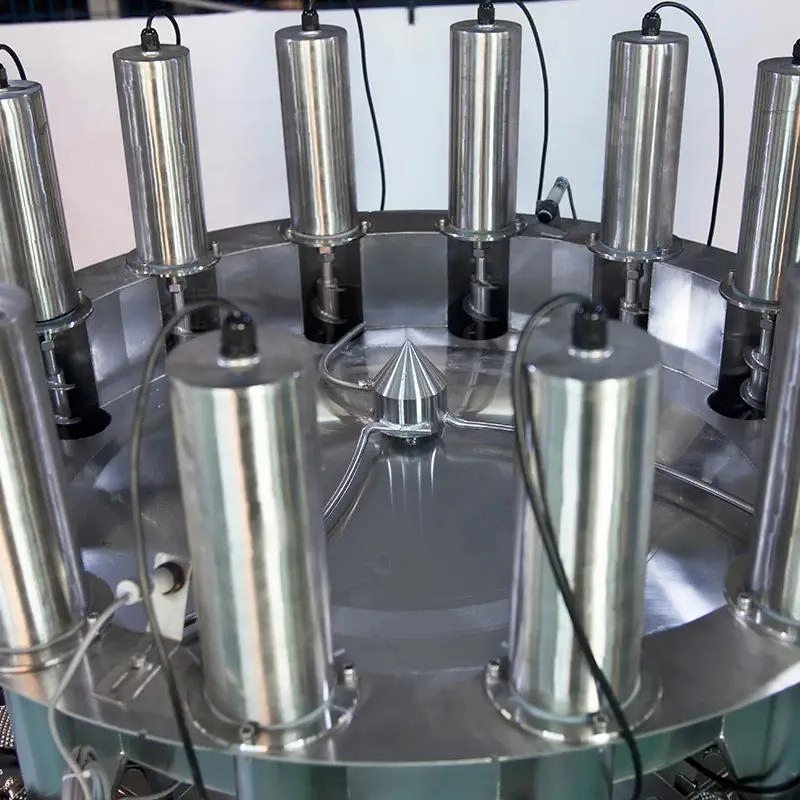

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Kenwei Multihead Weigher China – High-Speed, Precision Packaging Solutions

Kenwei, a leading multihead weigher manufacturer in China, stands at the forefront of automated weighing technology. Specializing in multihead weighers, metal detectors, linear weighers, and check weighers, Kenwei delivers unparalleled speed and precision for diverse packaging needs. Based in Guangdong’s Fusha High-tech Industrial Park, Kenwei integrates cutting-edge design with advanced manufacturing capabilities to provide one-stop automated weighing and packaging solutions customized to meet your exact requirements.

Our multihead weighers are engineered to ensure maximum efficiency and accuracy, helping businesses reduce material wastage while increasing packaging speed. Whether handling snacks, frozen foods, confectionery, or hardware components, Kenwei machines excel in performance, reliability, and ease of use. Clients benefit from our comprehensive support services—from professional installation and technical training to responsive after-sales assistance—ensuring seamless operation and long-term value.

What sets Kenwei apart is our commitment to innovation and customer satisfaction. Our integrated automated packing systems streamline your production line, boost productivity, and optimize your packaging process. With a solid reputation in the industry, Kenwei has become the trusted choice for companies seeking top-tier multihead weighers in China and beyond.

Explore our solutions to enhance your packaging efficiency with Kenwei’s high-precision multihead weighers. Visit https://www.kenweigroup.com/ to discover how we can customize advanced weighing technology for your business success.

Product Image

Qualification Certificate

ICR Polska/VC/LUL0139 Metal Detector

OIL CERTIFICATE OF CONFORMITY

Advanced Award for High Quality Development of Enterprises

Question you may concern

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

If you have any questions about our goods or services, please feel free to contact us.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

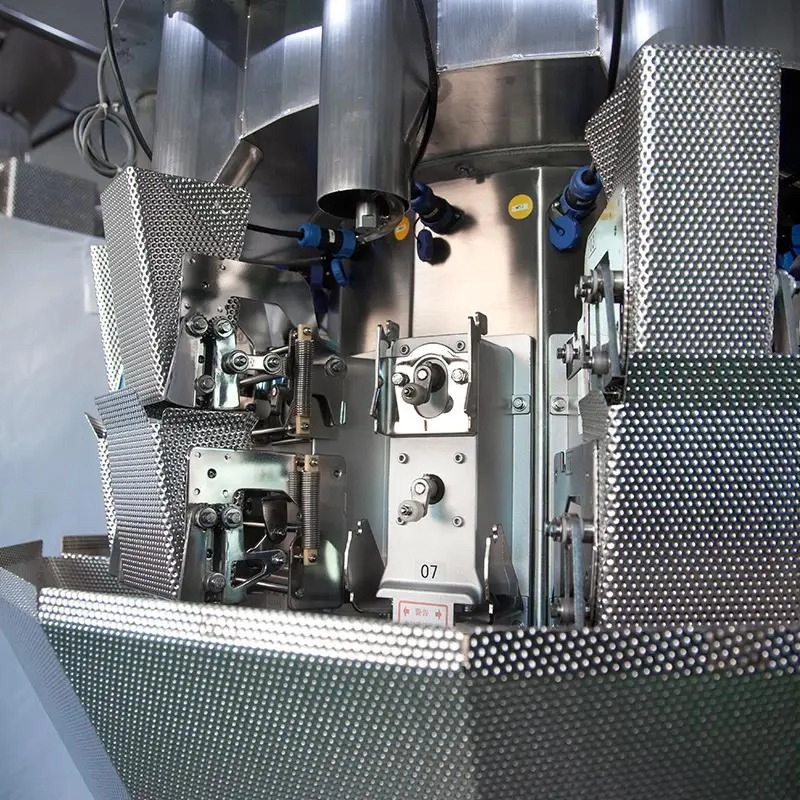

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei