Kenwei Metal Detector for Food Industry

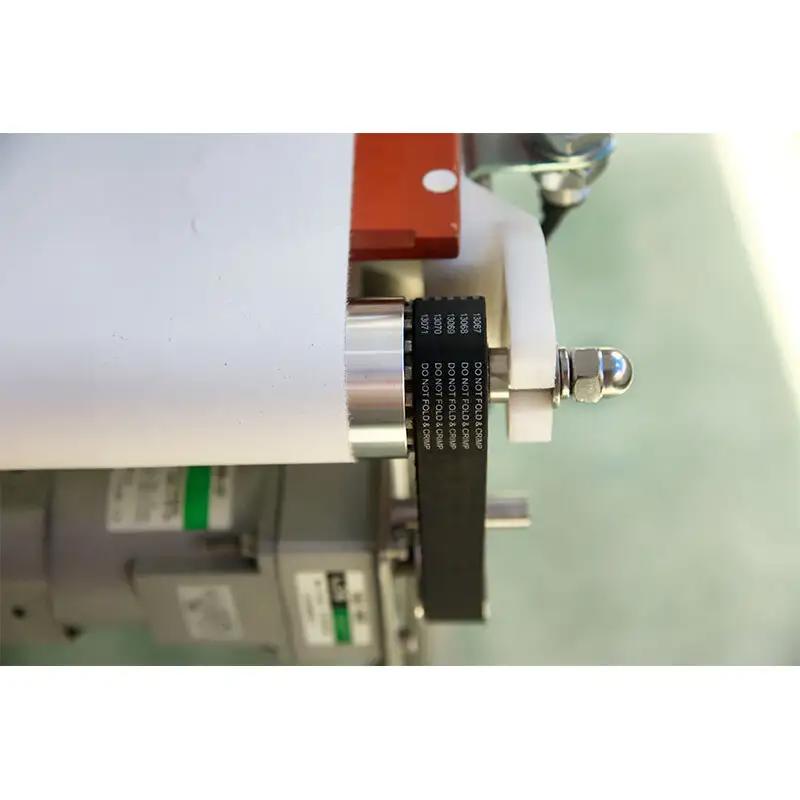

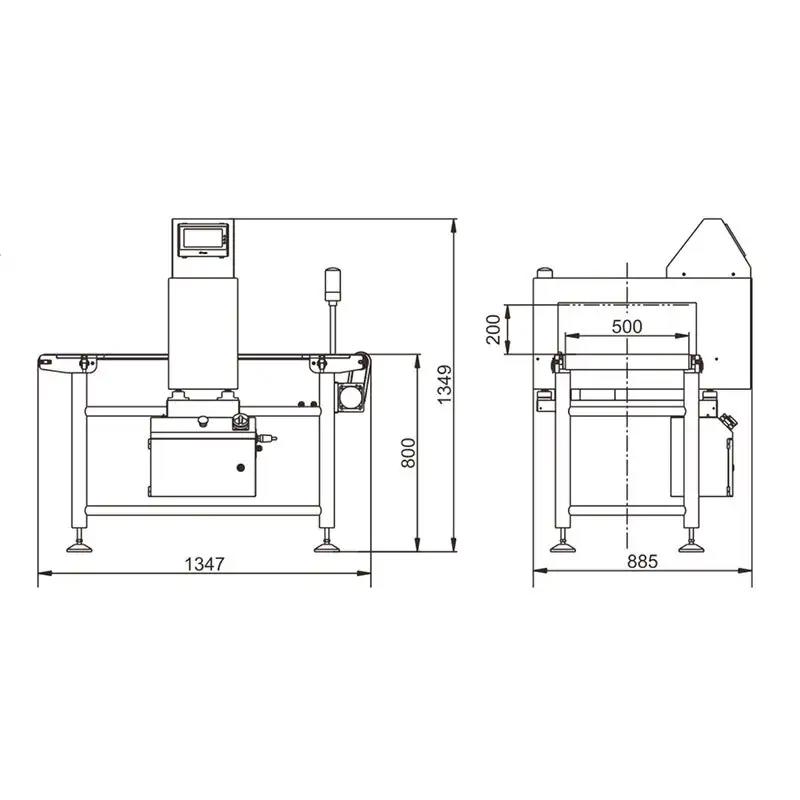

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Kenwei Metal Detector for Food Industry

Ensure product safety and quality with the Kenwei metal detector for the food industry—your trusted solution for contaminant detection in food processing lines. Purpose-built for the rigorous demands of modern food manufacturing, the Kenwei metal detector seamlessly integrates into your production flow to pinpoint and reject even the tiniest metal particles, safeguarding Kenwei reputation and consumer health.

As a powerful manufacturer famed for innovation, Kenwei delivers advanced metal detection systems engineered for high speed, outstanding precision, and consistent reliability. Our detectors are easy to operate, require minimal maintenance, and boast intelligent features tailored for diverse food applications, from baked goods to packaged snacks and more. Whether you run a small operation or a large-scale facility, our flexible designs and user-friendly interfaces make integration effortless, ensuring compliance with international food safety standards.

But with Kenwei, you don’t just get a machine—you receive end-to-end support, from consultation and customization to installation and after-sales service. Our commitment is to provide one-stop automated weighing and packaging solutions, also offering multi-head weighers, linear weighers, and check weighers to optimize your production line.

Join leading brands worldwide who trust Kenwei’s quality, expertise, and caring approach. Choose Kenwei metal detectors for your food industry needs and let us help you deliver products with confidence and care.

Learn more at: (https://www.kenweigroup.com/)

Picture Show

Certifications

Inflatable packaging airtight inspection machine-Utility Model Patent Certificate

Intellectual Property Management System Certification

FAQ

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei