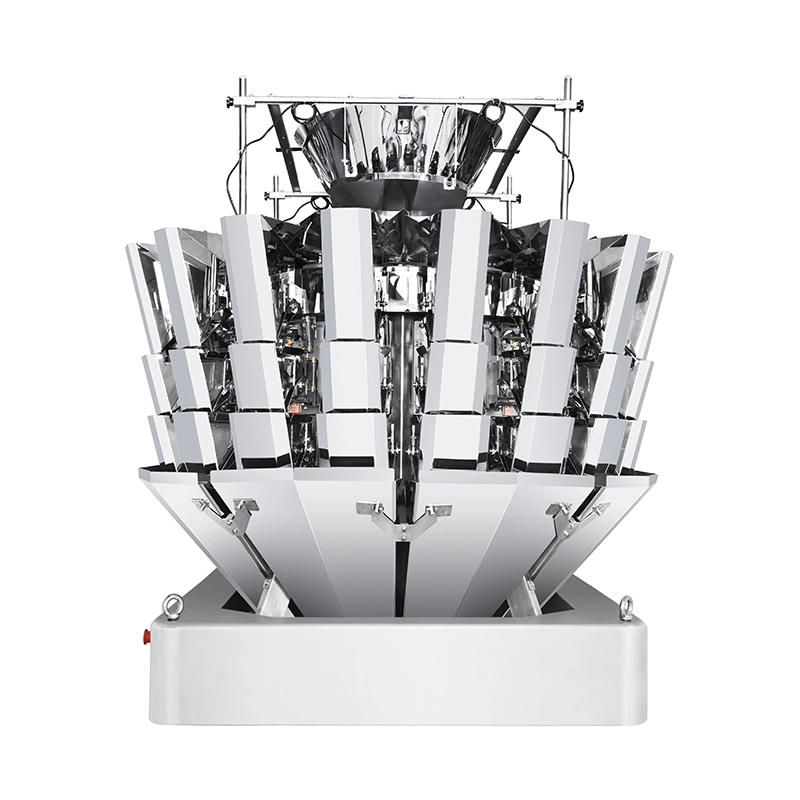

Kenwei Automatic Multihead Weigher — High-Speed Precision for Packaging

Automatic Multihead Weigher Overview

Kenwei's automatic multihead weigher is a reliable, high-performance solution for accurate portioning and packaging. As a leading manufacturer based in Guangdong, China, Kenwei specializes in multi-head weighers, metal detectors, linear weighers, and check weighers. Our machines combine speed, precision, and easy integration to meet diverse production needs.

Why Choose Kenwei?

Kenwei machines are built for consistent performance. Each automatic multihead weigher is designed to reduce giveaway, increase throughput, and improve product quality. We offer end-to-end support — from design and manufacturing to installation, training, and after-sales service — so customers can deploy equipment with confidence.

Key Features

- High speed and accuracy: Fast cycle times with precise weight control for stable results.

- Flexible feeding: Compatible with a wide range of products — from free-flowing snacks to irregular items.

- Customizable configurations: Multiple heads, discharge chutes, and combination logic to suit your product and line layout.

- Intuitive controls: Easy-to-use touch interface and recipe management for quick changeovers.

- Durable design: Food-grade materials and robust construction for long service life and low maintenance.

Applications

Kenwei automatic multihead weighers are widely used in the food industry and beyond. Typical applications include snacks, nuts, frozen foods, confectionery, pet food, and small hardware. The machine is also easy to integrate with sealing, bagging, and check-weighing systems for a complete packaging line.

Service & Customization

We understand every production line is different. Kenwei provides tailored solutions and quick technical support. Our team can help design custom layouts, adjust weighing strategies, and provide on-site installation and training to ensure smooth operation.

Get Started

Choose Kenwei for a dependable automatic multihead weigher that improves efficiency and product consistency. Visit https://www.kenweigroup.com/ to learn more or contact our sales team for a consultation and quote.

Detailed display

Qualification Certificate

Member of China Weighing Instrument Association

Combination Scale-Utility Model Patent Certificate

ICR Polska-VC-LU201109 Multihead Weigher

Q&A

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

14 Head Multihead Weigher Packaging Machine for Weighing and Packaging Dumplings Wontons

The weighing sensor has high-precision, high-standard professional performance and adopts intelligent multi-sampling stable mode to significantly improve weighing accuracy. It also has an intelligent fault alarm function, making maintenance more efficient and convenient. The equipment supports high-speed wrong material unloading, effectively avoiding material blockage. The overall structure adopts a highly integrated modular design, integrates CAN bus technology, and applies Modbus industrial standard communication protocol to achieve seamless integration of the combined weighing system and the packaging machine.

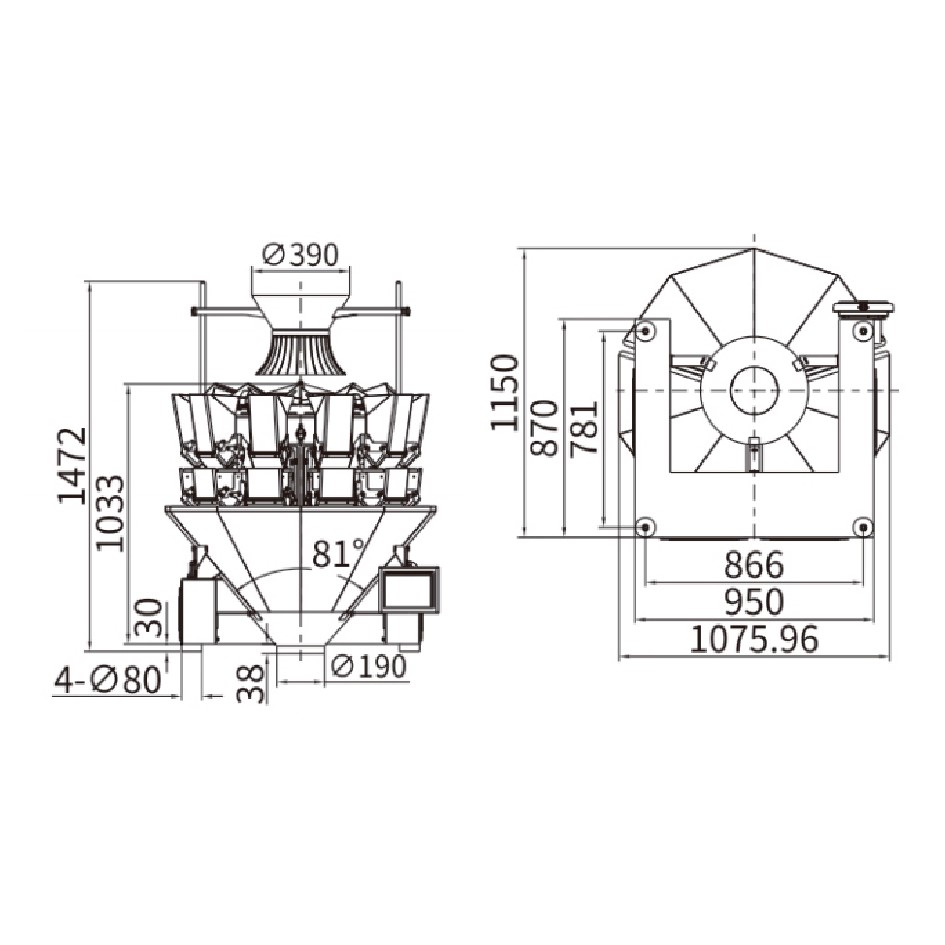

High Precision 3-Layer 18-Head Standard Weigher for Accurate and Efficient Weighing

The High-Precision 3-Layer 18-Head Standard Weigher is designed for accurate weighing of a wide range of materials, including granular, flake, round, irregular, and puffed items like nuts, seeds, candies, and snacks. It features a separate vibration plate for mixed material applications, a Ling-shaped hopper for faster and more concentrated discharge, a memory bucket for improved accuracy, and an integrated chassis for enhanced stability. Ideal for high-precision, efficient weighing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei