Guangdong Kenwei to Showcase Intelligent Packaging Solutions at the 137th Canton Fair 2025

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is delighted to announce its participation in the 137th Canton Fair, taking place from April 15–19, 2025, at the China Import and Export Fair Complex in Guangzhou, China. As a leading manufacturer of multihead weighers, checkweighers, and intelligent packaging machinery, Kenwei is proud to present its latest innovations and smart automation solutions to global visitors.

What to Expect at Kenwei’s Booth

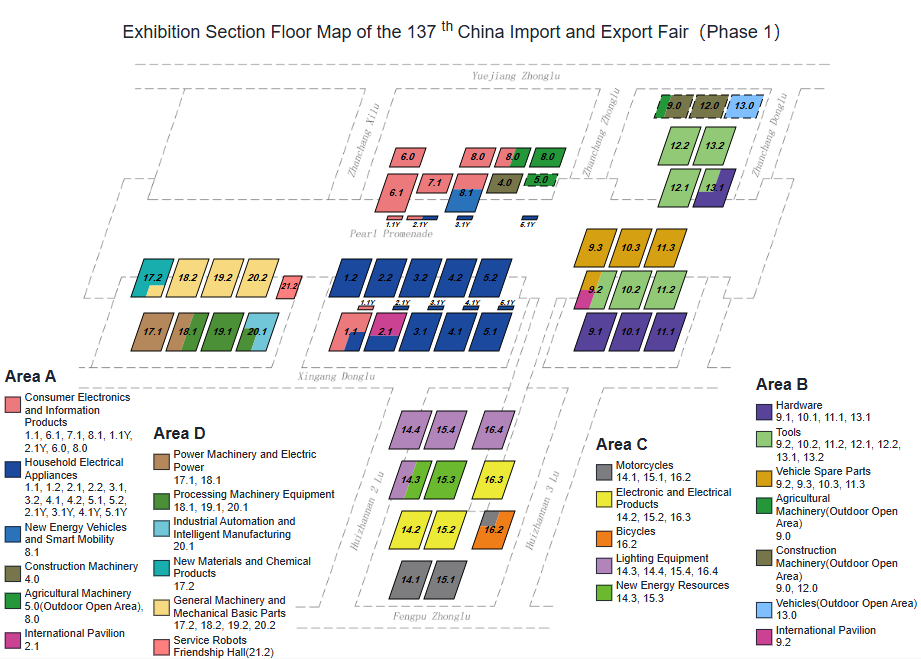

Visitors to Booth 19.1J06-7 & 20.1E42, Area D will have the opportunity to:

-

Explore our multihead weighers, checkweighers, and automatic packaging systems designed for high accuracy and efficiency.

-

Watch live demonstrations of our advanced intelligent weighing and packaging machines.

-

Learn about customized packaging solutions tailored to meet diverse industry needs.

-

Engage with our experienced R&D and sales teams to discuss cooperation opportunities.

Why Visit Kenwei at the Canton Fair?

With more than 18 years of expertise in R&D, manufacturing, and global service, Kenwei has become a trusted partner in the food, pharmaceutical, chemical, hardware, and household goods industries. Our high-speed, high-precision weighing and packaging equipment helps companies improve efficiency, ensure product quality, and drive sustainable growth.

Event Details

-

Exhibition: 137th Canton Fair 2025

-

Venue: China Import and Export Fair Complex, Guangzhou

-

Dates: April 15–19, 2025

-

Booth Numbers: 19.1J06-7 & 20.1E42, Area D

We sincerely invite partners, customers, and industry professionals to visit Kenwei at the Canton Fair 2025 and explore how our intelligent weighing and packaging solutions can create value for your business.

👉 Join us in Guangzhou to experience Kenwei’s innovation in intelligent packaging machinery!

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About Cooperation Process

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei