Integrating Multihead Weighers with Food Packing Machines

- Integrating Multihead Weighers with Food Packing Machines

- Why integrate a multihead weigher with your food packing machine?

- Key challenges when connecting multihead weighers to a food packing machine

- Choosing the right multihead weigher for your food packing machine

- Mechanical interfaces and conveyor alignment for reliable transfer

- Control system integration and communication protocols

- Packaging machine types and matching strategies for food packing machines

- Ensuring food safety, inspection and traceability in the integrated line

- Testing, commissioning and validation for food packing machines with weighers

- Layout, footprint and ergonomics for productive food packing machine lines

- ROI and cost considerations when integrating with a food packing machine

- Kenwei: a partner for integrated multihead weighers and food packing machines

- How Kenwei supports integration on food packing machine lines

- FAQ

- Q: Can any multihead weigher be connected to any food packing machine?

- Q: Where should inspection systems be placed in an integrated line?

- Q: How long does commissioning typically take for a new integrated line?

- Q: What maintenance is required to keep accuracy high on a multihead weigher?

- Q: How do I choose between a multihead weigher and a combination weigher for my food packing machine?

- Contact and next steps

- References

Integrating Multihead Weighers with Food Packing Machines

Why integrate a multihead weigher with your food packing machine?

Integrating a multihead weigher with a food packing machine delivers measurable improvements in accuracy, yield, and throughput for high-volume food lines. Multihead weighers are designed to combine many small, fast weighments to reach a target weight with minimal giveaway. When paired properly with a packing machine — such as a VFFS (vertical form-fill-seal), flow wrapper, thermoformer, or tray packer — they minimize product giveaway, reduce labor, and improve product consistency. For manufacturers pursuing efficiency and compliance, a well-integrated system is a core investment in competitiveness.

Key challenges when connecting multihead weighers to a food packing machine

Integration is more than bolting machines together. Common challenges include synchronization of discharge timing, matching material handling rates, managing dust and fines, ensuring sanitary design for washdown, and establishing reliable communication between control systems. Mismatches in timing can cause underfills, overfills, or packaging machine jams. Addressing these challenges up front reduces downtime and accelerates commissioning.

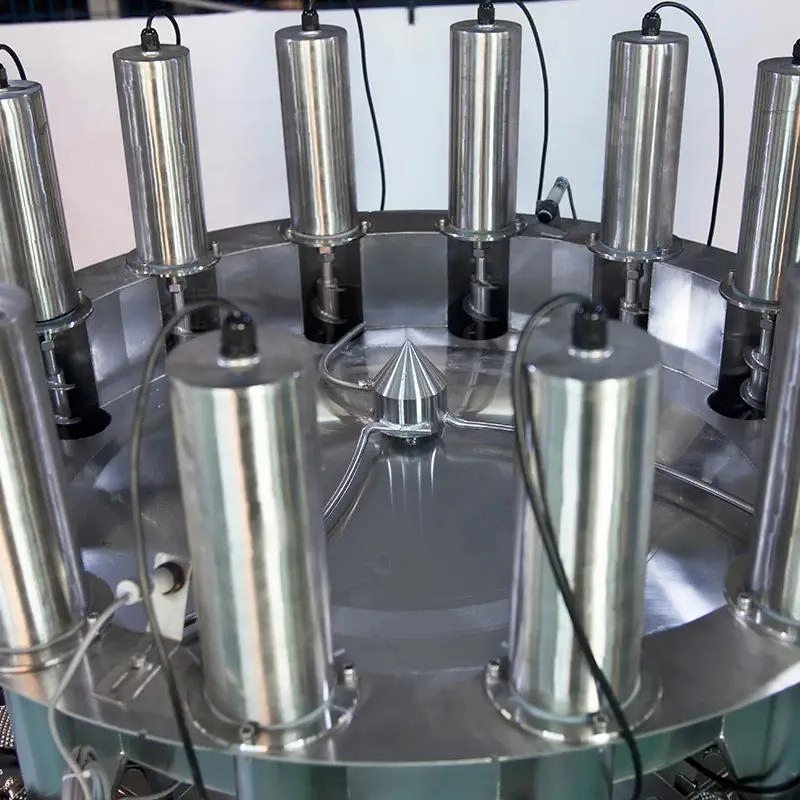

Choosing the right multihead weigher for your food packing machine

Selection starts with product characteristics and target throughput for your food packing machine. Key selection criteria include:

- Product type: free-flowing snacks differ from irregular frozen pieces or leafy greens. Product shape affects hopper design, dosing method, and vibration settings.

- Head count and accuracy: more heads usually yield higher speed and better accuracy for the same target weight, but cost and footprint increase.

- Throughput matching: ensure the weigher's maximum stable packs per minute aligns with the packing machine's capacity.

- Feed and distribution: upstream feeders, vibratory feeders, and distribution chutes must be sized to prevent starvation or overflow.

- Sanitation and materials: stainless steel finish, IP/NEMA rating for washdown, quick-change components for cleaning, and compliance to food safety standards.

Considering these factors early prevents costly retrofits during line balancing.

Mechanical interfaces and conveyor alignment for reliable transfer

Mechanical design is critical for smooth product transfer from a multihead weigher to a food packing machine. Typical elements include a timed discharge gate or bucket system, a short transfer conveyor or chute, and a buffer system to decouple differences in instantaneous flow. Pay attention to:

- Discharge geometry: chutes should minimize product drop height and orientation changes to protect fragile items.

- Transfer conveyors: low-acceleration belts or gentle flight conveyors reduce product breakage and dust.

- Buffering: small hoppers or star-wheel accumulators smooth out pulses when the weigher batch rate differs slightly from the packer cycle.

- Changeover design: adjustable guides and quick-change chutes speed product changeovers and reduce downtime.

Control system integration and communication protocols

Seamless communication between the multihead weigher and the food packing machine is essential for synchronized operation and data traceability. Modern systems use industrial protocols such as Ethernet/IP, PROFINET, Modbus TCP, or OPC UA. Integration considerations include:

- Recipe management: synchronized recipes ensure the weigher and packer switch parameters together for different SKUs.

- Status and alarms: shared signals for run, stop, jam, and product low help coordinate automatic stops to avoid waste.

- Data logging: weight distribution, rejection rates, and production counts should be logged centrally for QA and traceability.

- HMI integration: operators prefer a unified HMI or mirrored screens to avoid training on multiple interfaces.

Packaging machine types and matching strategies for food packing machines

Different food packing machines place different demands on multihead weighers. Matching strategy depends on the packer’s cycle speed, dwell time, and method of receiving product. Common pairings include VFFS, horizontal flow wrappers, thermoformers, and tray sealers. The table below summarizes typical throughput ranges and integration notes to help you choose the right combination.

| Packaging Machine Type | Typical Throughput (packs/min) | Integration Notes |

|---|---|---|

| VFFS (Vertical Form-Fill-Seal) | 30–120 | Requires timed discharge; buffer hopper often useful. Good for bagged snacks, nuts, and frozen veggies. |

| Horizontal flow wrapper | 40–200 | Continuous flow favoring steady feed; use continuous transfer conveyors and gentle metering. |

| Thermoformer (tray forming) | 20–120 | Often needs precise placement in trays; pick-and-place or synchronized drop systems required. |

| Pre-made pouch inserter / pouch filler | 15–80 | Timing critical for product pick and place; accumulation hoppers help maintain flow during packer motions. |

| Tray packer / robotic case packer | 10–60 | Often uses robotic sorting and vision; weighers feed trays or robots that place product precisely. |

Table source: industry benchmarks and manufacturer datasheets (examples include PMMI/Packaging World and Kenwei technical guides).

Ensuring food safety, inspection and traceability in the integrated line

Integration must preserve or enhance food safety. Typical safeguards include installing metal detectors or X-ray inspection immediately after product transfer or after packaging, and check weighers for final weight verification. Traceability requires capturing batch codes, lot numbers, and production data in a central system. This enables rapid recall capability and supports HACCP documentation. Ensure all contact surfaces are food-grade and that the design facilitates sanitation procedures.

Testing, commissioning and validation for food packing machines with weighers

Commissioning is where integration excels or fails. Recommended steps include:

- Factory acceptance testing (FAT): simulate production using the same product and bag style to prove throughput and accuracy.

- Site acceptance testing (SAT): run sustained production trials at line speed to validate robustness and changeover times.

- IQ/OQ/PQ (Installation/Operational/Performance Qualification): document that the system meets installation, operation, and performance requirements for regulatory and QA teams.

- Operator training: hands-on sessions for line operators and maintenance teams to reduce human errors and speed troubleshooting.

Layout, footprint and ergonomics for productive food packing machine lines

Efficient floor layout reduces product handling and minimizes maintenance dead zones. Consider the following:

- Access aisles: allow service doors to open and permit removal of major components without moving adjacent equipment.

- Elevations: align discharge heights to the packer feed point; use adjustable frames for fine alignment.

- Utilities: plan for power, compressed air, and washdown drains; place PLC and network connections in protected cabinets when possible.

- Ergonomics: design changeover steps to be reachable without ladders and include tool-less change parts where possible.

ROI and cost considerations when integrating with a food packing machine

Cost considerations include initial capital, installation and commissioning, operator training, and ongoing maintenance. Benefits include reduced giveaway, higher line yield, lower labor cost, and fewer quality disputes. A simple example illustrates potential savings:

Example (illustrative): assume a snack product with average giveaway reduction of 0.5 g per pack after integration. If the product value is $0.02 per gram, that's $0.01 saved per pack. At 100 packs/min running a single 8-hour shift (48,000 packs/day), daily savings are $480. Over a 250-workday year, savings reach $120,000—often justifying the initial equipment and integration cost within 1–3 years depending on line specifics.

Note: real ROI varies by product, labor costs, and current filling accuracy. Conduct a site-specific analysis before investment.

Kenwei: a partner for integrated multihead weighers and food packing machines

Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements. Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry.Our vision is to become the world's leading weighing packing machine manufacturer. Our website is https://www.kenweigroup.com/

How Kenwei supports integration on food packing machine lines

Kenwei's product portfolio includes Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, and food packing machinery. Core competitive advantages include high-speed performance, high precision, complete one-stop solutions for weighing and packaging, and strong after-sales service. Kenwei provides engineering support for mechanical interfaces, PLC and network integration, FAT/SAT procedures, and operator training—reducing the time from order to stable production.

FAQ

Q: Can any multihead weigher be connected to any food packing machine?

A: Not necessarily. Physical interfaces, discharge timing, control compatibility, and throughput must be matched. Select a weigher with appropriate head count, discharge type, sanitation rating, and control protocol for your packer.

Q: Where should inspection systems be placed in an integrated line?

A: For best food safety, place metal detectors or X-ray units after the product transfer but before primary sealing, and use a check weigher after packaging to verify final weight. Specific placement depends on product and compliance requirements.

Q: How long does commissioning typically take for a new integrated line?

A: Typical commissioning ranges from a few days for simple, well-matched systems to several weeks for complex lines requiring custom conveyors, robotics, or packaging formats. Proper FAT reduces on-site time.

Q: What maintenance is required to keep accuracy high on a multihead weigher?

A: Regular cleaning, calibration checks, vibration and feeder tuning, and prompt replacement of worn parts are essential. Preventive maintenance schedules and spare parts inventory shorten downtime.

Q: How do I choose between a multihead weigher and a combination weigher for my food packing machine?

A: Multihead weighers excel with particulate products and when high throughput plus accuracy are needed. Combination weighers (e.g., linear plus multihead hybrid) may be better for delicate products or when mixing multiple ingredients. Evaluate product fragility, weight distribution, and required speed.

Contact and next steps

If you are planning to integrate a multihead weigher with your food packing machine and need a turnkey solution—including design, installation, commissioning, and training—contact Kenwei to discuss line requirements and request a site-specific proposal. Visit https://www.kenweigroup.com/ or contact Kenwei sales for product catalogs and integration support.

References

- Kenwei Group technical materials and company information (https://www.kenweigroup.com/)

- PMMI / Packaging World — industry articles and equipment benchmarks

- Food Engineering / Food Manufacturing — articles on inspection and line integration

- Packaging machinery manufacturer datasheets and FAT/SAT best practices

Throughput Comparison: Multihead Weigher Options for Pickles

What are the application scenarios of cookie packaging machine?

Key Features to Evaluate in a Pill Counter Machine

What are the application scenarios of pouch packing machine?

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

Rotary Packaging and Weighing System with Multihead Weigher for Peanuts Melon Seeds JW-B8

Kenwei Rotary Packaging and Weighing System with Multihead Weigher is an efficient food packing machine designed for peanuts and melon seeds. This rotary packaging machine ensures high-speed, precise weighing and sealing, making your production smarter and faster.

Automatic Weighing and Canning Filling System for Efficient Packaging Solutions JW-B24

The Kenwei Automatic Canning and Weighing Filling System offers a fully integrated solution for efficient food packaging. Featuring a multihead weigher, Z-type conveyor, vibrator feeder, and capping machine, it automates feeding, weighing, filling, and labeling with high accuracy. Perfect for snacks, puffed foods, fruits, hardware, and granular materials in cans. Ideal for modern production lines.

Single Head Belt Linear Weigher for Vegetable Product Weighing

The Single Head Belt Linear Weigher is constructed from food-grade stainless steel, making it ideal for materials with slight stickiness, such as brown sugar, black sugar, and industrial salt, which have low fluidity. This linear scale features a single hopper with a 15-liter capacity, designed for weighing larger materials efficiently.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei