The Development and Future of China’s Machinery Industry in the Era of Automation

China’s machinery industry plays a vital role in national economic growth and modernization. While automation and intelligent manufacturing are progressing rapidly, the industry still faces challenges such as technological gaps, limited innovation, and structural inefficiencies. This article explores China's industrial automation trends, development history, and future path toward Industry 4.0.

The machinery industry is a pillar of national economic development. It provides core equipment for a wide range of sectors and is deeply connected to the modernization and transformation of the economy. As China progresses toward becoming a global manufacturing power, machinery automation has become a key driver of industrial upgrade and innovation.

Policy Background: “Made in China 2025” and Strategic Goals

The “Made in China 2025” initiative outlines a national strategy focused on:

-

Innovation-driven development

-

Quality-first manufacturing

-

Green and sustainable practices

-

Structural optimization

-

Talent-centric growth

To achieve the goal of becoming a world-class manufacturing powerhouse, China’s machinery sector must adopt advanced automation technologies and shift toward intelligent, integrated, and eco-friendly production.

The Development Gap: From Manufacturing Giant to Technology Leader

China's machinery manufacturing has made significant progress, especially after the reform and opening-up period. However, compared with developed economies, China still lags behind in several key areas:

-

Lack of core technologies: Many high-end technologies are still dependent on foreign companies.

-

Weak innovation capabilities: A shortage of skilled professionals and independent R&D efforts hampers growth.

-

Late industrialization: China's machinery industry started nearly a century after nations like the U.S., resulting in a slower catch-up pace.

Despite having the world’s largest manufacturing base, China still struggles to achieve technological self-reliance and innovation leadership.

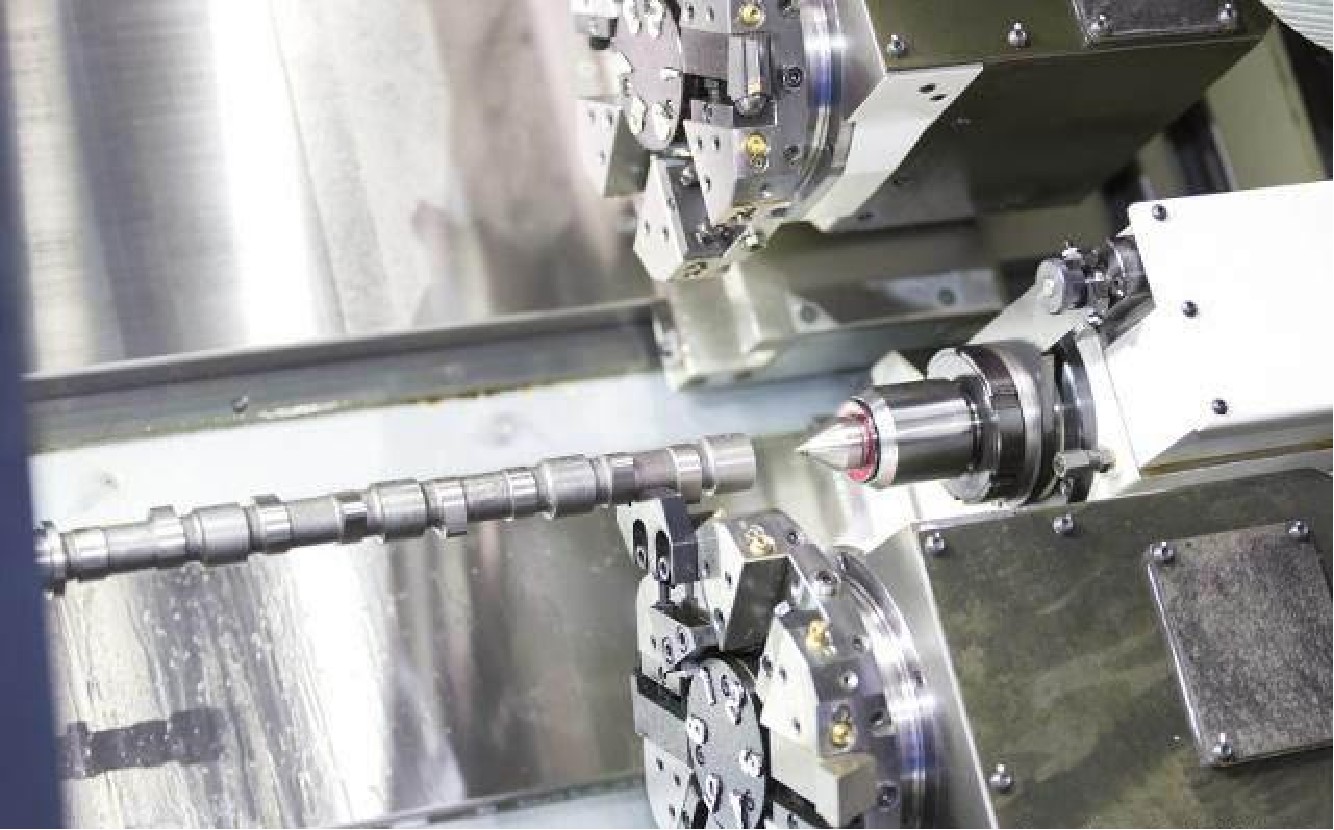

Current Landscape of Mechanical Automation

With increasing demand for efficiency, automation in machinery has become a necessity rather than a luxury. Today’s automated equipment delivers multifunctionality, precision, and energy efficiency. Key advantages include:

1. Time-Saving and Labor Reduction

Modern automated systems can run pre-programmed tasks without constant human supervision. They include safety features like self-diagnostics and alarms, improving safety and operational uptime.

2. Material Efficiency

Automated machinery offers higher accuracy than manual processes. For instance, combination weighers like those from Guangdong Kenwei achieve weighing accuracies as precise as 0.1–0.5g, minimizing raw material waste and improving production yield.

3. Ease of Maintenance

Many modern machines feature modular designs, allowing for easier disassembly and maintenance. For example, combination weighers are designed for fast part replacement and minimal downtime.

Food Packaging Machinery: A Rising Focus

Within the machinery sector, food packaging automation is gaining traction due to increasing awareness of food safety. Combination weighers are core components in this space. Global leaders like Ishida and Yamato have long dominated the market, but domestic players like Guangdong Kenwei have made significant technical strides.

Kenwei, in particular, has:

-

Developed innovative features

-

Extended product shelf life up to 2 years

-

Achieved global competitiveness in technology and production scale

Future Development Trends

To keep pace with global industrial evolution, China's machinery industry is shifting toward:

1. Intelligent Manufacturing

Integration of AI, IoT, and big data allows machines to make decisions, predict failures, and adapt to changing conditions.

2. Integrated Systems

Modern manufacturing systems use computer-integrated technology that merges engineering design, production, quality control, and management into a unified digital workflow.

3. Eco-Friendly Solutions

As environmental awareness grows, machinery is increasingly designed to reduce emissions, save energy, and support green manufacturing practices.

Conclusion: Embracing Industry 4.0

China's machinery industry is undergoing a critical transformation. While challenges persist, the integration of automation, intelligence, and eco-conscious design is paving the way toward a stronger, more sustainable future. As China continues its push toward Industry 4.0, high-tech innovation and smart manufacturing will define the next chapter of its industrial success.

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

About Cooperation Process

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei