Metal Detectors in Food and Pharmaceutical Industries: Ensuring Safety and Quality

Metal detectors are essential for industrial production, especially in food, pharmaceuticals, and cosmetics. Integrated into weighing and packaging systems, they ensure product safety, detect metal contaminants, and improve production efficiency. This guide explores selection, maintenance, and future trends of metal detectors.

The Importance of Metal Detectors in Industry

Metal detectors play a critical role in industrial production by detecting metal contaminants in products. In sectors such as food, pharmaceuticals, and cosmetics, metal foreign objects can pose serious health risks. Therefore, using a metal detector is crucial to protect consumers and maintain product quality.

The detection principle typically relies on electromagnetic induction or X-ray technology. As products pass through the detector, the presence of metal alters the electromagnetic field or X-ray readings, allowing the system to identify potential hazards and prevent contamination.

Integration with Weighing and Packaging Systems

Automated weighing and packaging systems frequently handle high-volume products, making integration with metal detectors essential. In the food industry, these systems ensure vegetables, fruits, meat, and other products are free from metal contaminants. In pharmaceutical production, metal detectors safeguard drugs from contamination during packaging and weighing, guaranteeing compliance with safety standards.

How to Choose the Right Metal Detector

Selecting the right metal detector requires careful consideration of:

-

Sensitivity: Different metal probes offer varying sensitivity. Choose one that meets your production line requirements.

-

Application Scope: Ensure compatibility with the types of products and production environments.

-

Ease of Operation: Simple, intuitive systems enable employees to start quickly.

-

Maintenance and Upkeep: Consider maintenance cycles and ease of part replacement.

-

After-Sales Service: Reliable support ensures smooth long-term operation and quick problem resolution.

-

Maintenance and Upkeep Tips

To ensure long-term stability and accuracy:

-

Clean the probe regularly: Dust or residue can affect sensitivity.

-

Replace parts on schedule: Follow manufacturer guidelines.

-

Verify and adjust sensitivity annually: Ensures continued precision.

-

Proper storage and handling: Protect equipment from sunlight, impact, and moisture.

-

Future Trends in Metal Detector Technology

With technological advancement and market demand, metal detectors are evolving toward:

-

Higher intelligence and automation: Incorporating AI and computer vision for enhanced precision.

-

Advanced sensing technologies: Using nanomaterials, MEMS, and microfluidic chips.

-

Multi-functional integration: Combining temperature, humidity, odor, and image detection.

-

Lightweight design: Enhancing mobility and ease of installation.

-

Data analysis optimization: Improving the accuracy and usefulness of detection data.

About Kenwei

Guangdong Kenwei Intellectualized Machinery Co., Ltd. has specialized in high-precision weighing and packaging equipment for over 18 years. Our product range includes multihead combination weighers, linear weighers, metal detectors, check weighers, and automated packaging systems.

As a professional metal detector manufacturer, Kenwei is dedicated to providing reliable, efficient, and energy-saving solutions, helping enterprises ensure product safety while optimizing production lines.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

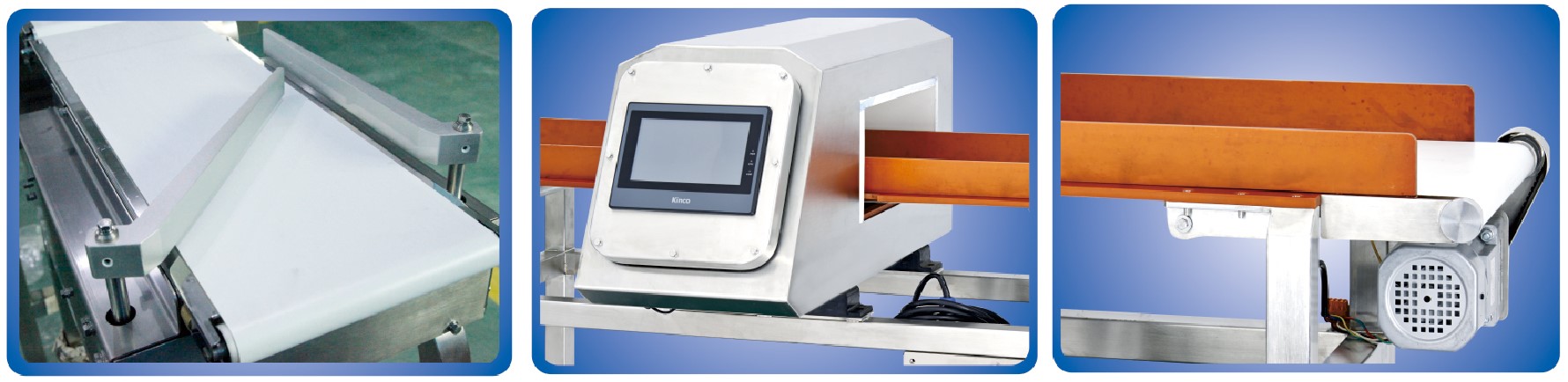

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei