Elevate Your Packaging Efficiency with Kenwei's Advanced Multihead Weigher Machine

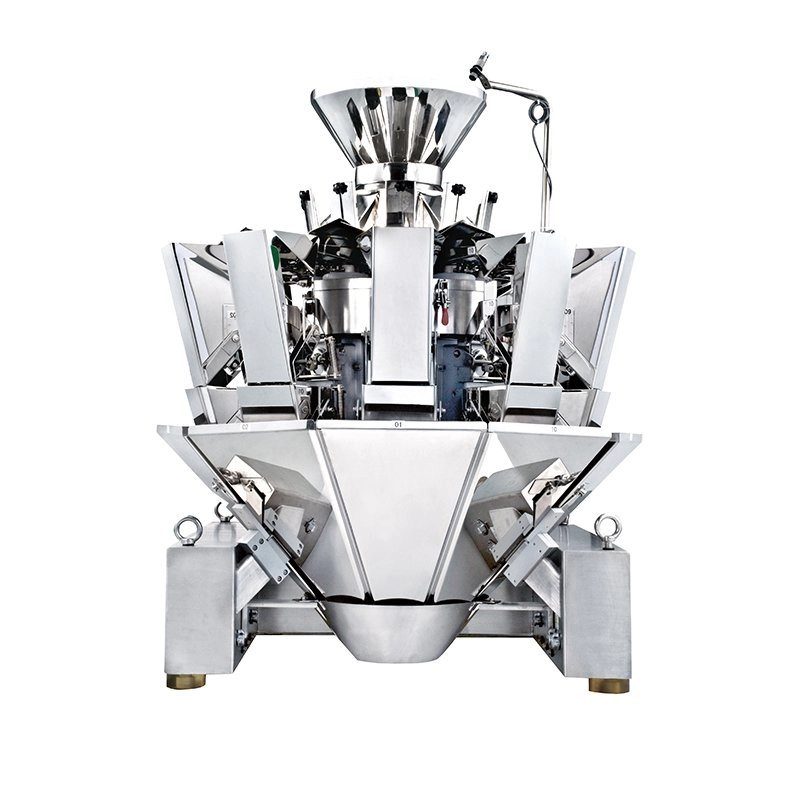

In the fast-paced world of food processing and packaging, precision and efficiency are paramount. That’s where Kenwei steps in, offering cutting-edge solutions tailored to meet the diverse needs of industries dealing with granular and small solid products. The 2-Series multihead weigher machine from Kenwei is engineered for accuracy and designed for versatility, handling everything from tea and seeds to coffee beans, chocolate, and raisins with ease.

The Kenwei 2-Series stands out with its adoption of high-accuracy load cells from leading brands, ensuring that every weigh is consistent. The machine boasts an impressive resolution improved up to two decimals, a feature that minimizes product giveaway and maximizes profit. To streamline operations, Kenwei has incorporated a program recovery function, drastically reducing the likelihood of operational failures and maintaining consistent performance even through variations in product and environment.

User experience is at the forefront of the design. The Kenwei multihead weigher machine features an intuitive, user-friendly help menu, which contributes to easy operation and reduces the learning curve for new operators. With a 100-program capacity, the machine is versatile enough to meet a wide range of weighing requirements, adapting seamlessly to different product types and target weights. Its multi-segment weight calibration support further ensures adaptability and optimized performance.

Kenwei's commitment to continuous improvement is evident in the innovative features of the 2-Series. The linear amplitude of each head can be adjusted independently, allowing for precise control over product flow and ensuring consistent fill levels. Its modular design is focused on ease of use, with upper brackets engineered for simple removal and cleaning, reducing downtime and improving hygiene. The mold-making process and uniform design standards contribute to better interchangeability of spare parts, streamlining maintenance and reducing the need for specialized tools.

Beyond the core features, Kenwei offers a suite of optional enhancements that tailor the multihead weigher machine to specific requirements. From various feeding options to specialized discharge systems, the Kenwei 2-Series can be customized to meet the unique needs of your production line, enhancing throughput and ensuring the highest standards of product quality. Choose Kenwei and experience the difference precision engineering can make in your operations.

Kenwei 2025 Annual Gala Highlights | Unite for Transformation · Empower the Future with Intelligence

Peanut Vertical Weighing and Packing Solution

Efficient Weighing and Packaging Solution for Small-Pack Pork Jerky

A smart weighing and packaging solution for soft gummy candies.

Automated Fresh Shrimp Packaging with 14-Head Multihead Weigher

About Cooperation Process

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

Leak Proof Multi Head Combination Weigher for Small Particle&Powder

Discover the Kenwei Leak Proof Multi Head Combination Weigher for Small Particle & Powder. This advanced multihead weigher machine ensures high-precision weighing, leak-proof performance, and efficiency. Ideal for various industries needing accurate combination weigher solutions.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei