Smart Manufacturing and Automation in China’s Food Industry: The Rise of Intelligent Packaging and Robotic Systems

The Deep Integration of Automation and Internet Technology in the Food Industry

In recent years, the convergence of automation and next-generation Internet technologies has catalyzed a transformative shift in the global food industry. In China, this integration is especially evident, reshaping how food is processed, packaged, and delivered. Traditional manual processes are rapidly giving way to intelligent systems involving robotic cooking, automated packaging, AI-driven sorting, and logistics management.

China's food industry is evolving from simple "eating enough" to "eating well." This shift, driven by changing consumer demand and economic development under the “new normal,” has led to the rapid emergence of multi-billion-dollar food conglomerates. These enterprises are increasingly supported by end-to-end smart manufacturing solutions—including food and packaging machinery that spans the entire industrial chain from raw processing to final packaging and palletizing.

Unprecedented Technological Progress and Investment

Over the past five years, China has seen its most intense wave of investment in food technology. The sector has become a hub for concentrated innovation, technical expertise, and patent activity. This focus has led to major breakthroughs in key technological areas and the development of advanced equipment across multiple segments, including:

-

Grain and oil processing

-

Fruit and vegetable sorting

-

Meat and poultry automation

-

Aquatic product handling

-

Liquid food packaging systems

The independent innovation capability of Chinese companies has improved significantly, with many now owning core technologies and advanced equipment featuring high levels of intelligence, automation, and environmental efficiency.

Smart Equipment and Core Technology Breakthroughs

China has made remarkable strides in designing and manufacturing a wide range of intelligent food machinery and automation solutions. Key advancements include:

-

Non-thermal food preparation technologies

-

Degradable food packaging materials

-

Real-time safety inspection and online quality monitoring

-

Traceability systems that span the entire food production chain

-

Internet of Things (IoT)-based remote control and diagnostics

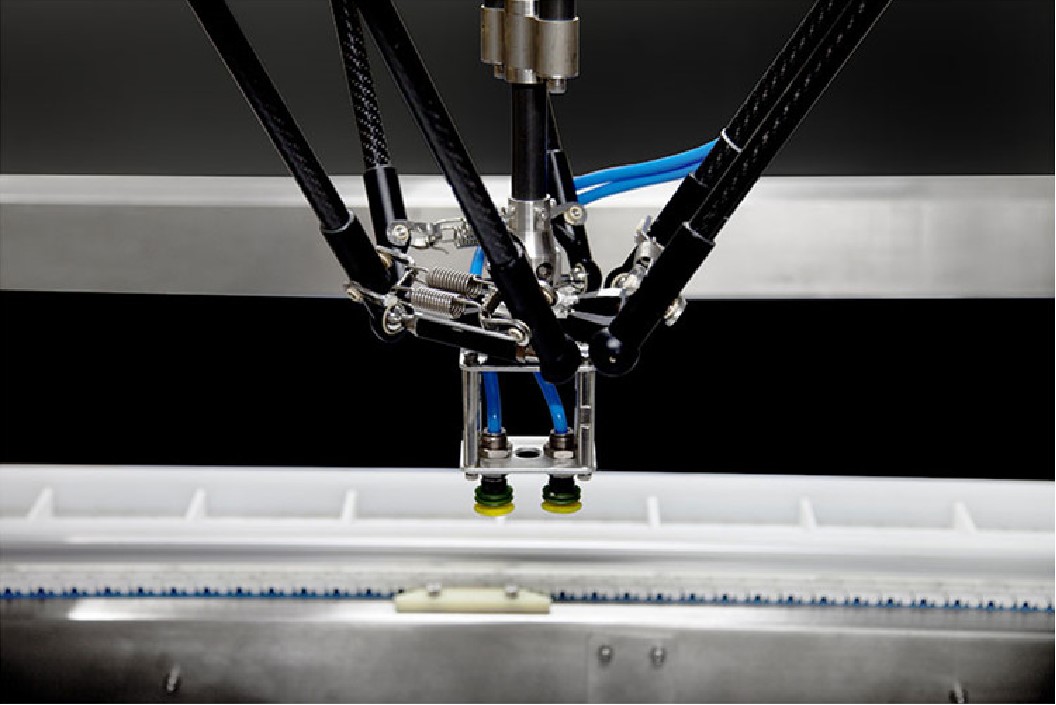

A prime example is Kenwei’s Parallel Manipulator JW-D1100, a cutting-edge robotic system designed for high-speed sorting and transfer of various materials across multiple industries, including food, pharmaceuticals, electronics, plastics, and handicrafts.

Key features of the JW-D1100 include:

-

Maximum speed: 150 picks per minute (P/M)

-

Repeat accuracy: ±0.1 mm

-

Maximum load capacity: 3,000 g

-

Seamless integration: Compatible with front-end checkweighers, metal detectors, X-ray inspection systems, and other automated packaging line equipment

-

High precision and strong stability: Ideal for complex, multi-station tasks

-

User-friendly interface: Touchscreen HMI with multi-axis control for points, arcs, and 3D movement

-

Smart functions: Teaching mode, overload shutdown protection, multi-station scheduling

This highly versatile robotic solution supports greater production efficiency and ensures high performance in demanding industrial environments.

Commitment to Innovation and Global Leadership

At Kenwei, we firmly adhere to our core values:

“Stability is the key to savings,” and “Professional manufacturing, excellent quality, and integrity in management.”

We are committed to:

-

Fusing weighing and packaging technology with next-gen automated production systems

-

Developing highly stable and efficient packaging solutions

-

Supporting industrial automation to lower production costs and boost operational productivity

-

Becoming a globally respected innovator in smart food packaging and automation technologies

Conclusion

As China’s food industry continues its digital transformation, the integration of AI, IoT, and robotics is setting new benchmarks for safety, speed, and efficiency. With sustained investment, a growing talent base, and stronger IP ownership, China is poised to become a global leader in intelligent food manufacturing and automation systems.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei