The Importance of Multihead Packing Machines in Modern Packaging Industry

- What is a Multihead Packing Machine?

- Key Components and Technology

- Why Multihead Packing Machines Are Essential

- 1. Accuracy and Reduced Waste

- 2. High-Speed Packaging

- 3. Hygiene and Product Quality

- 4. Versatility Across Industries

- 5. Long-Term Cost Efficiency

- Key Features of Multihead Packing Machines

- Choosing the Right Multihead Weigher

- Future Trends in Multihead Packing

- Conclusion

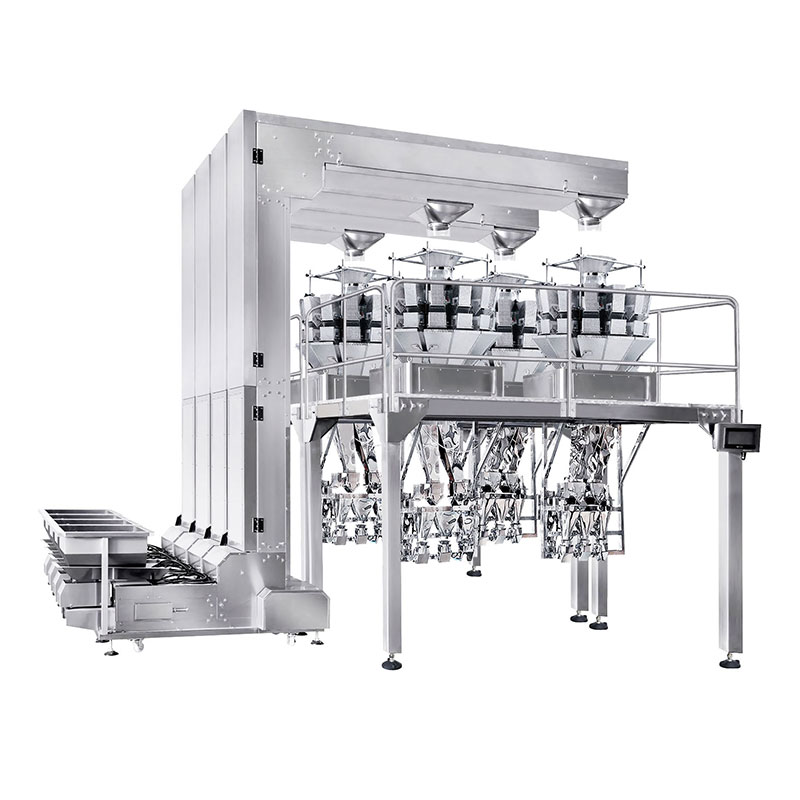

Multihead packing machines are essential for industries seeking speed, accuracy, and efficiency in packaging. With precise weighing technology, they reduce product waste, save costs, and maintain consistency. From food to pharmaceuticals, multihead weighers and automatic packaging machines ensure high productivity, hygiene, and long-term cost benefits.

What is a Multihead Packing Machine?

A multihead packing machine is advanced equipment designed to weigh and pack products with high precision. Using multiple weighing heads, the system calculates and distributes exact product portions into packaging containers, minimizing waste and ensuring product consistency.

The working principle includes:

-

Product Loading – Items enter the top hopper via the infeed system.

-

Distribution – Products are separated into individual weigh hoppers.

-

Combination Weighing – The system calculates the most accurate weight combination.

-

Packaging – The exact portion is released into the packaging unit.

This advanced process guarantees speed, hygiene, and reliability, making it an ideal automatic packaging machine for various industries.

Key Components and Technology

-

Infeed System – Ensures efficient product delivery.

-

Weighing Heads (Multihead Weigher) – Provide precise weight measurements.

-

Control Panel – Advanced computer calculates weight combinations.

-

Discharge System – Transfers accurate portions to packaging.

-

HMI Interface – User-friendly display for real-time monitoring.

Modern multihead weighers use automation, touch-screen interfaces, and remote monitoring, making them faster, smarter, and easier to operate.

Why Multihead Packing Machines Are Essential

1. Accuracy and Reduced Waste

With precision of 0.1–0.5 grams, multihead weighers minimize giveaway, maximize efficiency, and reduce costs.

2. High-Speed Packaging

Capable of up to 120 packs per minute, these machines enhance efficiency compared to manual packaging.

3. Hygiene and Product Quality

Built with food-grade stainless steel, they ensure contamination-free packaging, crucial for food and pharmaceuticals.

4. Versatility Across Industries

Applicable in:

-

Food & Snacks – Cereals, frozen foods, dried fruits, confectionery.

-

Pharmaceuticals – Tablets, capsules, and powders with strict compliance.

-

Cosmetics – Creams, powders, and personal care products.

-

Hardware – Small items like screws, bolts, and mechanical parts.

5. Long-Term Cost Efficiency

Though initial investment is high, businesses save money over time through reduced labor, higher efficiency, and lower waste.

Key Features of Multihead Packing Machines

-

High-Speed Weighing for bulk production

-

Precision Control with smart load cells

-

User-Friendly Interfaces for easy operation

-

Durability with stainless steel structure

-

Automatic Adjustments for different product types

-

Integration Options with form-fill-seal machines, conveyors, and checkweighers

Choosing the Right Multihead Weigher

When investing in a multihead packing machine, businesses should consider:

-

Product Type – Dry, wet, granular, or powdered.

-

Weighing Accuracy – Advanced load cell technology.

-

Production Volume – High-speed for bulk, standard speed for smaller businesses.

-

Integration – Compatibility with existing packaging lines.

-

Maintenance – Easy-to-replace parts for reduced downtime.

Future Trends in Multihead Packing

-

AI Integration – Smarter algorithms for improved accuracy.

-

IoT Connectivity – Remote monitoring and predictive maintenance.

-

Sustainability – Compatibility with eco-friendly and biodegradable packaging.

-

Compact Designs – Space-saving modular systems for flexible production.

Conclusion

Multihead packing machines have revolutionized modern packaging with unmatched accuracy, speed, and efficiency. From food processing to pharmaceuticals, they help businesses cut waste, improve hygiene, and scale production effectively.

Investing in a multihead weigher or automatic packaging machine ensures consistency, cost savings, and long-term growth. For innovative and reliable solutions, contact Kenwei today and upgrade your packaging efficiency.

About Solution suggestions

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei