Kenwei Automatic Weigher: Boosting Accuracy, Speed, and Efficiency in Modern Production

Kenwei Automatic Weigher delivers unmatched precision, speed, and reliability for food and industrial production lines. From reducing labor costs to ensuring consistent quality, it’s the go-to solution for businesses seeking high efficiency and accurate weighing.

An automatic weigher is a specialized machine designed to deliver precise weight measurements, widely used in the food industry and beyond. Its applications span metrology, quality control, and other industrial processes, ensuring consistent results for a variety of products.

As the demand for automated weighing systems grows, accurate sensor calibration becomes increasingly important. Proper calibration ensures that measured weights match actual product weights, preventing inaccuracies and maintaining product quality.

Key Benefits of the Kenwei Automatic Weigher

1. Reliability and Consistency

Automatic weighers ensure dependable results by weighing the same amount consistently, regardless of container size or shape. Unlike manual weighing, these machines remove subjective human error, delivering highly accurate measurements every time.

2. Higher Speeds of Operation

In production lines, speed matters. Automatic weighers can:

-

Save time by automating weight calculations.

-

Deliver precise and consistent measurements.

-

Reduce manual weighing errors.

-

Improve overall product quality through accuracy.

User-Friendly Control Interface

The Kenwei CT-2000 model offers a simple control interface for easy adjustments. Built-in safety features prevent operation if incorrect weights are detected, ensuring accuracy and preventing costly mistakes.

Versatility Across Industries

Kenwei automatic weighers are adaptable to various sectors, from food processing to industrial manufacturing. They can be customized to specific production needs while remaining a cost-effective option for frequent, large-scale weighing operations.

Future-Ready Technology

With automatic weighing systems, businesses benefit from:

-

Accurate and consistent results for better product quality.

-

Efficient processing that reduces downtime.

-

Reliable systems that ensure continuous operation.

-

Error reduction through automated control.

Kenwei Weighing Solutions

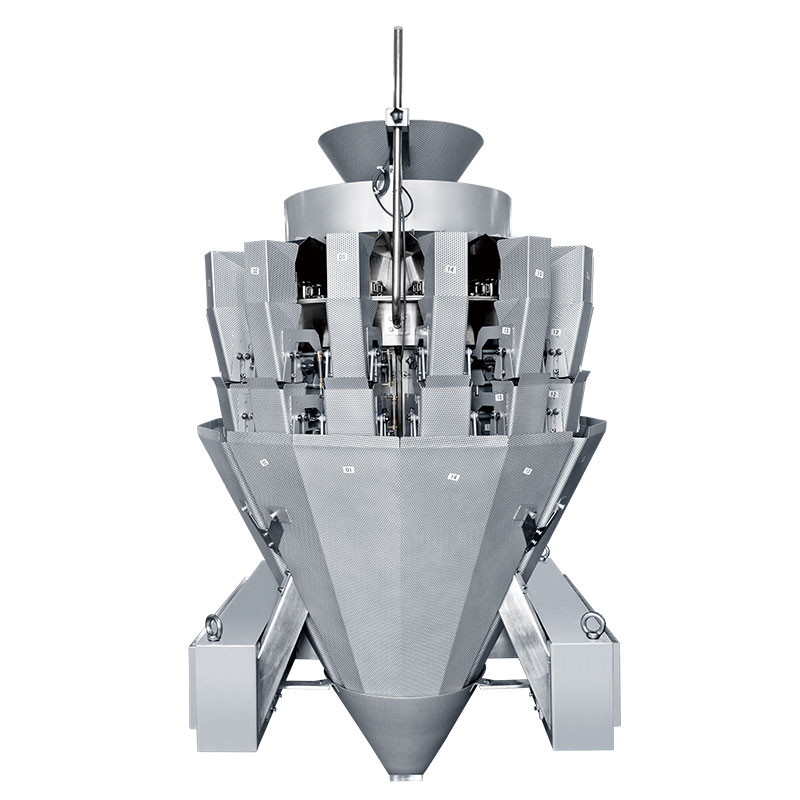

Multihead Weigher

Perfect for packaging multiple products at once, enhancing throughput, and reducing labor costs.

Linear Weigher

Ideal for quick, accurate single-product weighing, cutting error rates and production waste.

Check Weigher

Ensures every package meets required weight specifications, improving quality control and compliance.

About Kenwei

Kenwei specializes in advanced weighing and sorting machines that improve speed, accuracy, and efficiency in production lines. Their solutions cater to diverse industries, helping businesses optimize processes while reducing operational costs.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About After Sales Support

How about the after-sales service?

Warranty :2 years

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei