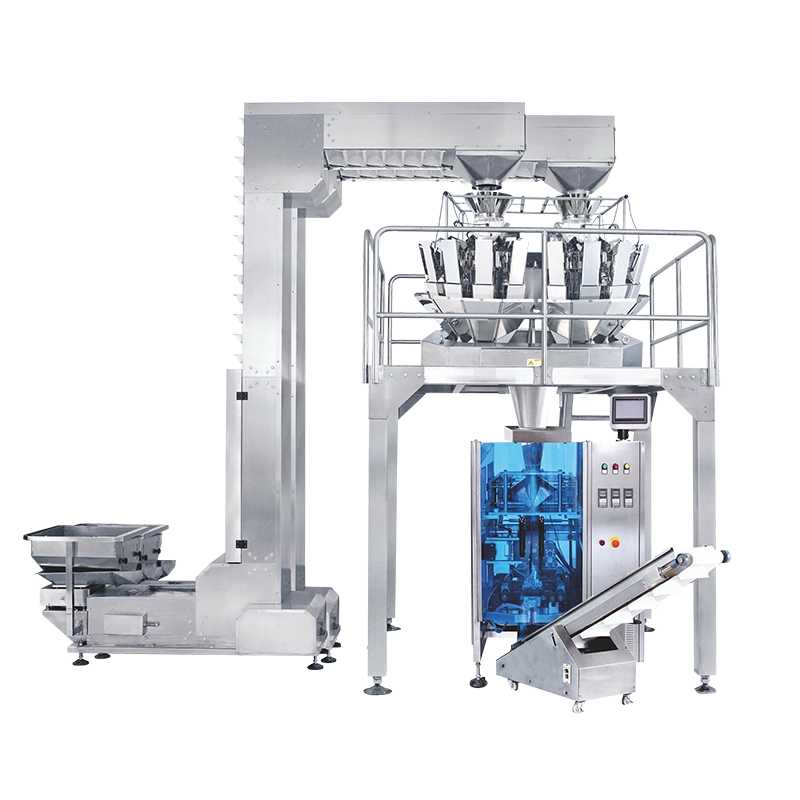

Automatic weighing packing machine for jelly drops 10 head cheese multihead weigher filling equipment

A complete set of filling equipment consists of a vibrating feeder, a z conveyor, 10 head cheese combination scale, a working platform and a horizontal conveyor. Among them, 10 head cheese combination scales play the most important role in the whole set of equipment. The 10 head cheese combination scales are suitable for soft and viscous materials such as cheese, QQ sugar, marshmallow, preserved fruit, preserves and so on. The following are the mechanical characteristics and product characteristics of 10 head cheese multihead scales: 1. Speed adjustable rotary top cone is suitable for different product feeding. 2. Enhanced linear vibrator improves the flowability of material. 3. The declinational special linear vibrator pan, ensure smooth feeding. 4. 60°dimple discharge chute contributes to less sticky problems. 5. Optional weighing type material detection, accurate control of feeding time, material thickness, to ensure the accuracy of the weighing; 6. The whole cast aluminum thickening machine case enhanced the strength of the machine, and shorten sample stable time. For more information about various high quality machinery,please email via kenwei@multiweigh.com.cn. Lick us on website:/ Skype us by :Spight Mao Call us via:0086-0760-22629231

Kenwei Showcases Intelligent Weighing & Packaging Solutions at Sino-Pack 2026

Kenwei 2025 Annual Gala Highlights | Unite for Transformation · Empower the Future with Intelligence

Peanut Vertical Weighing and Packing Solution

Efficient Weighing and Packaging Solution for Small-Pack Pork Jerky

A smart weighing and packaging solution for soft gummy candies.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Single Multihead Weigher Mixing And Weighing Packaging System For Weighing Packaging Mixing Materials JW-B26

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

Combined weighing and powder packing machine with vacuum feeder JW-B6

The system includes a vacuum feeder, multihead weigher, and vertical packaging machine.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei