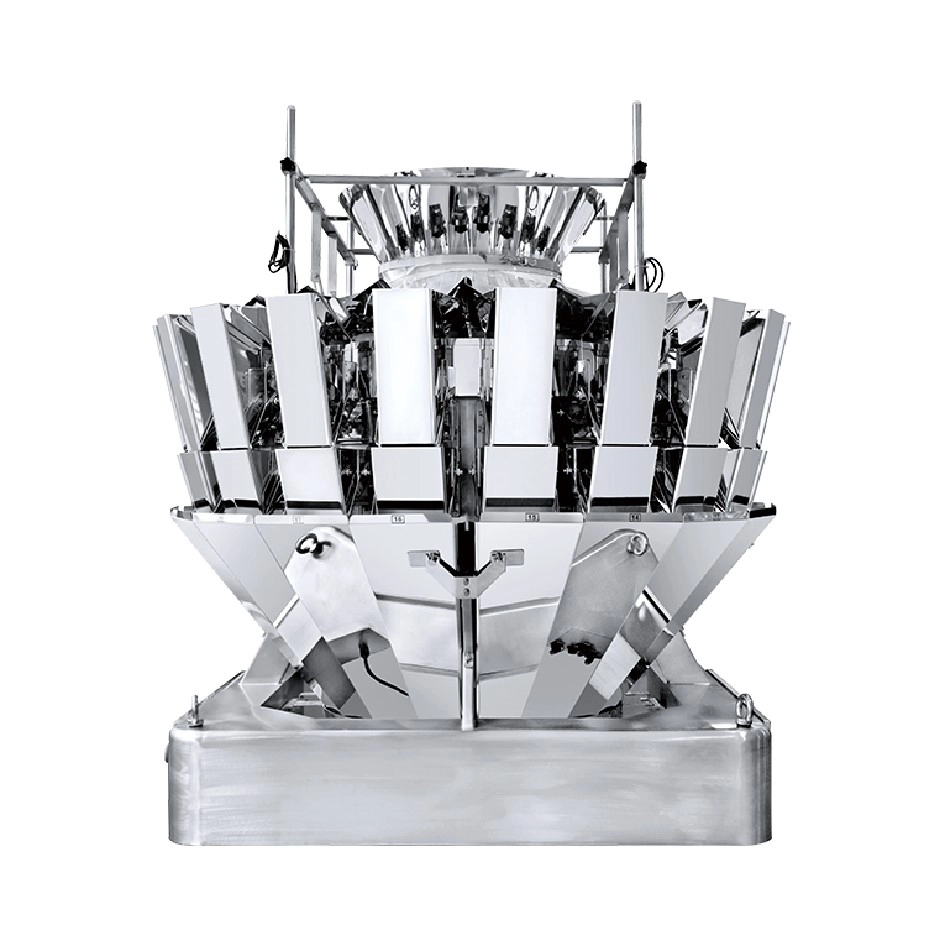

Semi-Automatic Manual Weigher for Seafood Packaging Machine

The Semi-Automatic Manual Feeding Combination Scale is designed for efficient, manual feeding and automatic weighing. It is ideal for materials with low fluidity or those unable to automatically feed, such as seafood, aquatic products, meat, and other irregular materials. With a thoughtfully designed balance table layout, the scale is user-friendly and easily operated by a single person. Its compact size and intuitive design make it a reliable and convenient solution for precise weighing in various industries.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 500 sets/year |

Feature

● Manual feeding with automatic weighing, ideal for materials with poor flowability.

● Optimal combination of weight hoppers ensures accurate target weight and efficient automatic feeding.

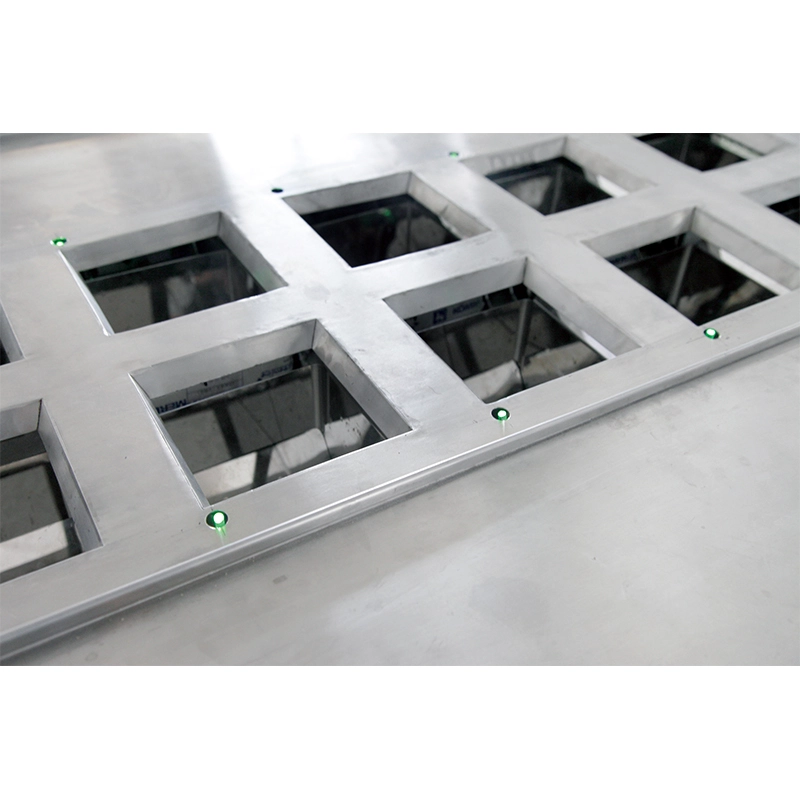

● Special high-precision load cells ensure exceptional accuracy and reliability.

● Intelligent multiple-sampling stable mode enhances weighing precision for consistent results.

● Built-in intelligent fault alarm system facilitates easy maintenance and reduces downtime.

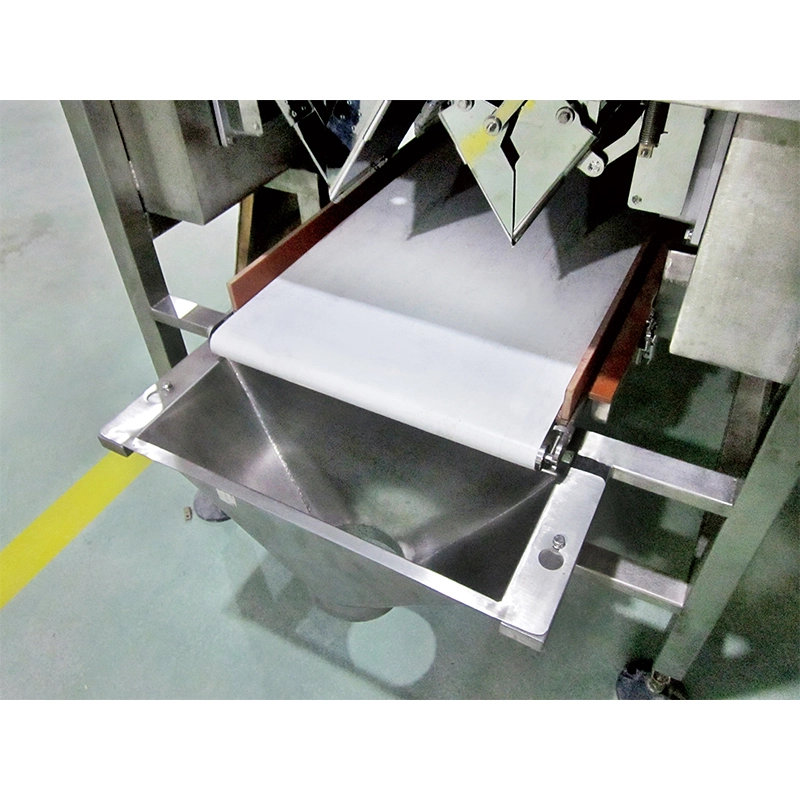

● High-speed staggered discharging function prevents material blockages and ensures smooth operation.

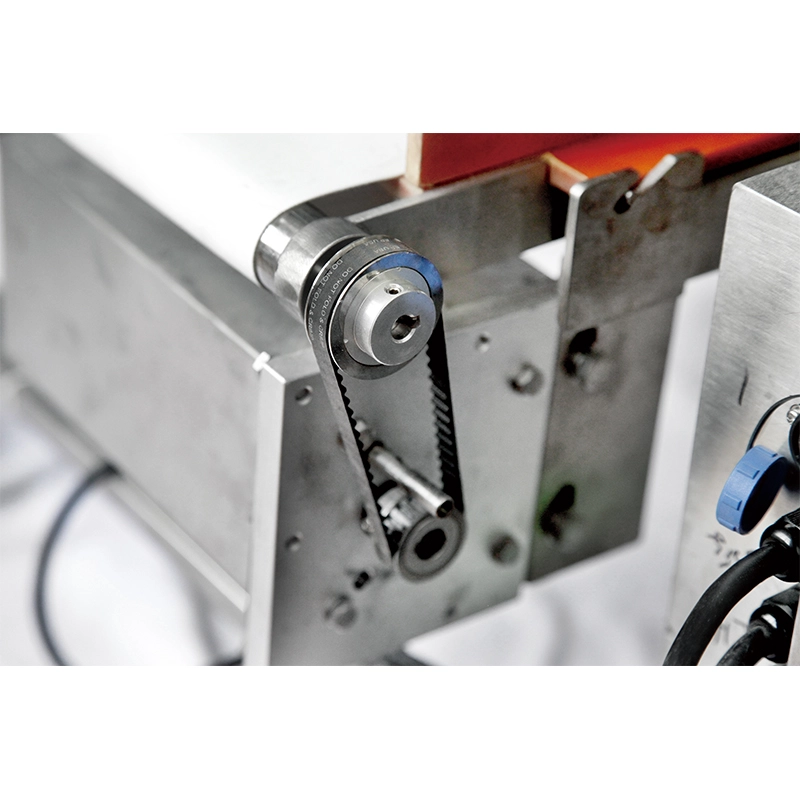

● Advanced integrated modular design, featuring CAN bus technology, enhances system performance and scalability.

● Utilizes the Modbus industry-standard communication protocol, allowing seamless integration between the multihead weigher and packaging machines for efficient production.

Mechanical Character

Technical Specification

|

Model |

JW-A12 |

JW-A12 |

|

Identify Code |

A12-2-4 |

A14-2-4 |

|

Weighing Range |

50-1000g |

50-1000g |

|

Accuracy*1 |

X(0.5) |

X(0.5) |

|

Max Speed*2 |

30P/M |

30P/M |

|

Hopper Volume |

3L |

|

|

Control Panel |

10.1'' Touch Screen |

|

|

Options |

Dimple Plate/Timing Hopper/Printer/Reject Device |

|

|

Driving System |

Step Motor |

|

|

Power Requirement |

220V/ 800W/50/60Hz |

|

|

Packing Dimension(mm) |

1700(L)*1100(W)*900(H) |

1900(L)*1100(W)*900(H) |

|

Gross Weight |

220kg |

250kg |

| *1: Can refer to the national standard GB/T27738-2011 or the international Legal Organization No.61 International Recommendation OIML R61 2004(E) | ||

| *2: Depends on product shape, product density, target weight, etc. | ||

Application

This system is ideal for weighing materials with poor flowability, such as seafood, aquatic products, meat, Chinese medicinal herbs, and other similar materials. It effectively handles products that are difficult to feed automatically, ensuring accurate and consistent weighing for a wide range of challenging materials.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

Automatic Multihead Weigher for Stick and Bar-Shaped Materials

High Precision 0.5L Mini Multihead Weigher for Tea, Coffee Beans, and Granules Packaging

12-Head Manual Belt Multihead Weigher for Large Block Weighing and Packaging

20-Head Multihead Weigher with Dual Output for Efficient Weighing of Mixed Products

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei