Kenwei Multihead Weigher Software — High-Speed Precision Weighing Solution

Overview of Kenwei Multihead Weigher Software

Kenwei Multihead Weigher Software is designed for manufacturers and packagers who need fast, accurate, and reliable weighing control. Backed by Guangdong Kenwei’s full-service manufacturing and support, the software makes multi-head weighers smarter and easier to operate. It combines a simple interface with powerful tools for recipe control, performance monitoring, and remote troubleshooting.

Key Features

- Intuitive touch-screen interface for quick setup and operation.

- Recipe management to switch products and weights with a single touch.

- Real-time data logging and reporting for production tracking and compliance.

- Advanced combination algorithms to maximize speed and minimize giveaway.

- Remote diagnostics and firmware updates to reduce downtime.

- Multi-language support and user access control for secure operations.

Benefits for Your Operation

With Kenwei software, lines run faster and more accurately. The intelligent weighing algorithms improve pack consistency while lowering product giveaway, which saves material costs. Operators spend less time on adjustments thanks to clear prompts and automated optimization. Managers gain visibility with downloadable reports that help monitor yield, uptime, and reject rates.

Seamless Integration and Customization

The software is built to integrate easily with existing equipment — PLCs, checkweighers, metal detectors, printers, and line controllers. Kenwei offers customization to meet special product or packaging requirements, plus full installation, training, and after-sales support from a professional team located in Zhongshan, Guangdong.

Why Choose Kenwei

Kenwei combines decades of experience in multi-head weighers and packaging machinery with a commitment to fast, thoughtful service. Our one-stop automated weighing and packaging solutions ensure the software and hardware work together reliably, helping you reach higher productivity and consistent quality.

Learn more or request a demo at https://www.kenweigroup.com/.

Qualification Certificate

Combination Scale-Utility Model Patent Certificate

ICR Polska/VC/LU201108 Metal Detector

Turntable Follow Filling Equipment-Utility Model Patent Certificate

FAQ

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

If you have another questions, please feel free to contact us.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Combined weighing and packaging machine with screw feeder for powder materials

The Kenwei combined weighing and packaging machine with screw feeder is ideal for powder packaging. This advanced weighing and packaging machine of powder ensures high precision and efficiency, making it your top choice power packaging machine for powder materials.

Super High Precision Mini Multihead Weigher for Accurate Small Granule Weighing

The Mini Multihead Weigher is a high-precision weighing device designed for accurate measurement of small particles. Featuring an ultra-small 0.5L hopper and a low-vibration design, it operates smoothly and efficiently. Ideal for precise quantitative weighing of products such as Chinese medicine tablets, tea, seeds, monosodium glutamate, and other small granules. With a 2-year warranty, it offers the longest quality assurance period in the industry.

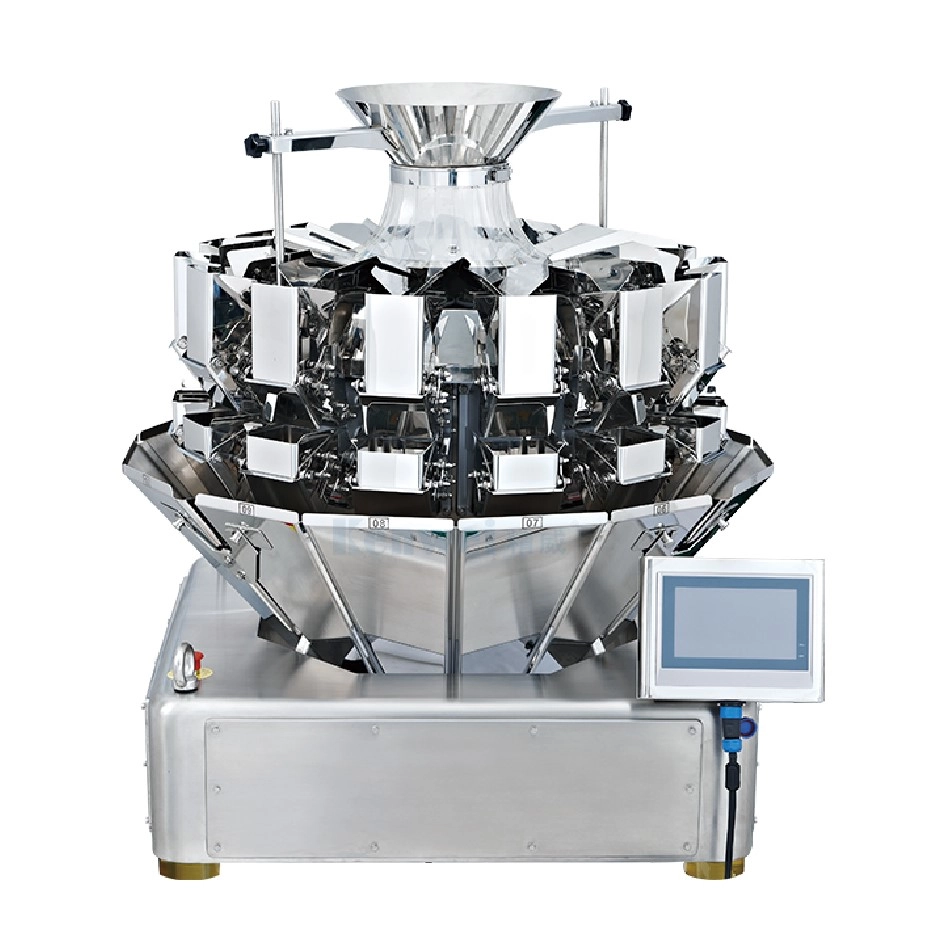

High-Precision 10-Head and 14-Head Combination Scales for Multifunctional Packaging of Leisure Foods

The standard combination weighing scale is a versatile weighing device available in five configurations, including 10, 12, and 14 heads. The 14-head model can achieve a maximum weighing speed of up to 120 bags per minute. With a wide range of applications, it is ideal for weighing materials such as candy, melon seeds, jelly, frozen goods, and more. The standard combination weighing scale is one of Kenwei's most popular products due to its reliability and performance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei